PLEASE NOTE: This webpage will NO LONGER be updated. There is no support for these files and plans.

PLEASE NOTE: If you choose to build this or something similar, please consult with physicians, technicians and/or clinicians.

PLEASE NOTE: We are getting some AMAZING feedback. Some Frequently Asked Questions are now posted below.

Thank you so much for all of your interest. It takes a village!

DIY Instructions and Files

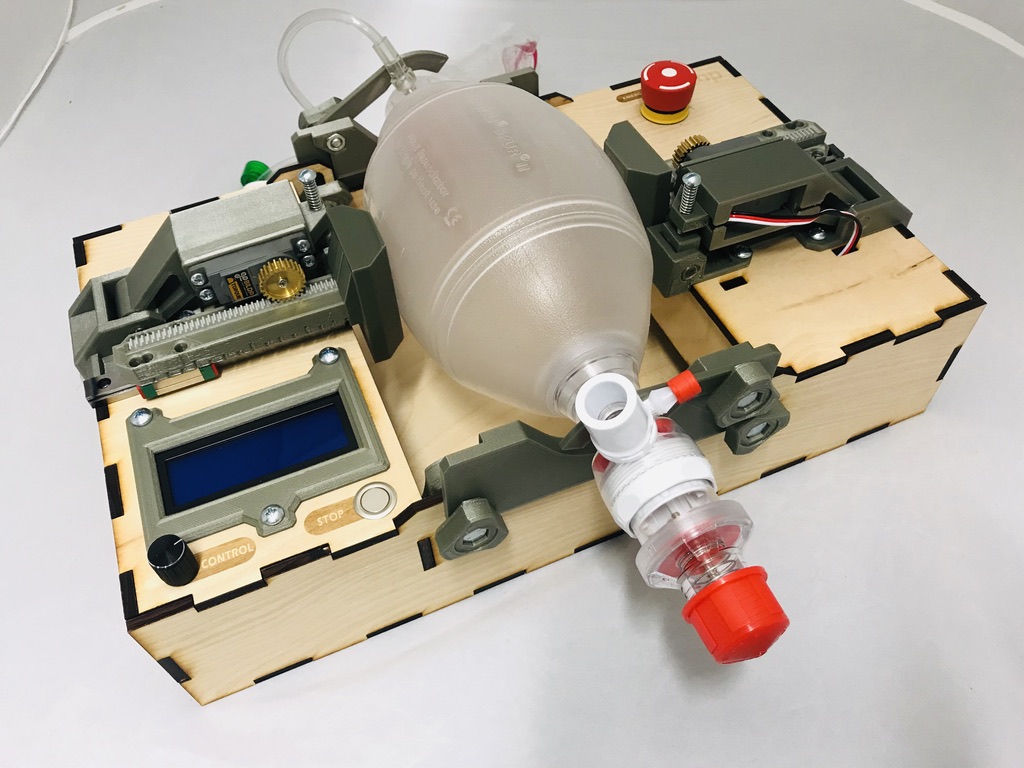

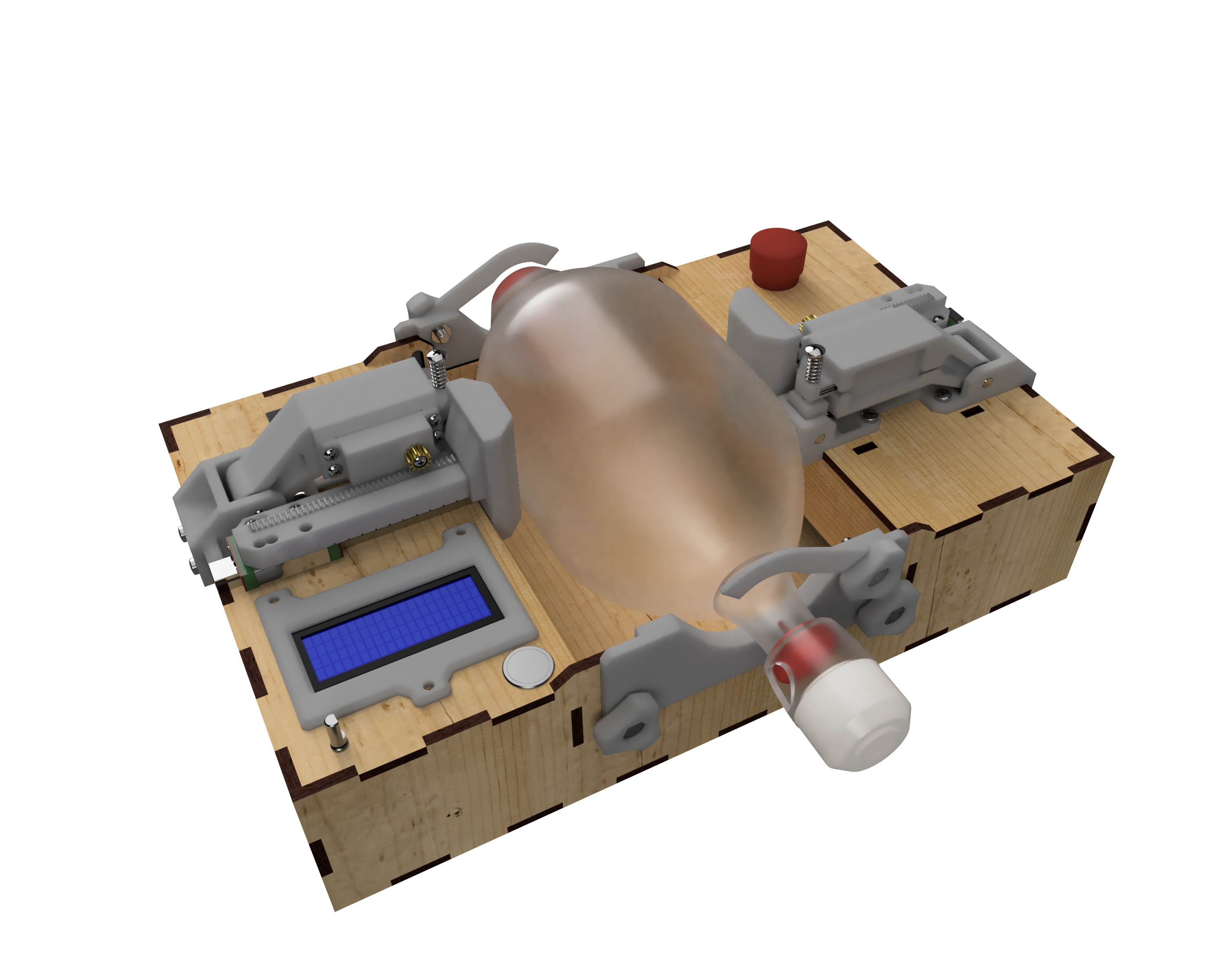

The ApolloBVM is a controllable, automated add-on solution to the existing and widely available Bag Valve Mask (BVM). The device compresses the BVM with a mechanical system that is able to provide consistent and accurate ventilation with positive-pressure. This solution exists within the top range of high-acuity limited-operability (HALO) ventilator solutions with an a priori design to produce volume and pressure cycled ventilation that includes positive end-expiratory pressure (PEEP) and enriched oxygen sources. The ApolloBVM is a rapidly scalable solution with a clinician-informed end-to-end design that repurposes the existing BVM global inventory toward widespread and safe access of hospital-grade mechanical ventilation. |

ApolloBVM Initial Prototype | ApolloBVM Acrylic Version 1 |

Skills

Assembly of the ApolloBVM should be possible with an intermediate to advanced machine assembly skill level. Operation of the device can be completed with intermediate expertise using the proper documentation, instructions, and files. Repair and maintenance of the ApolloBVM would be possible using this same documentation. Advanced knowledge would be required to access motion control and code framework to make gross modifications to the core functionality of the device.

_2020-Apr-04_08-45-31PM-000_CustomizedView11276532177_jpg.jpg) ApolloBVM Version 0 |  ApolloBVM Version 1 |

Parts BOM

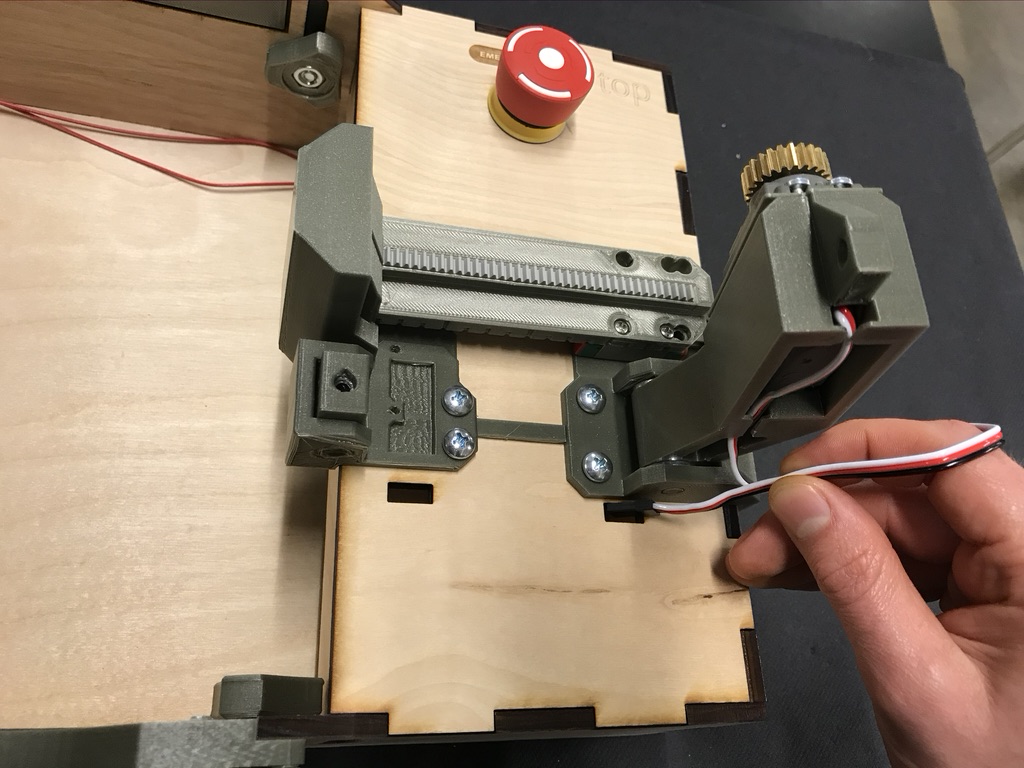

- Motors (2x) - goBILDA 2000 Series Dual Mode Servo (2000-0025-0002)

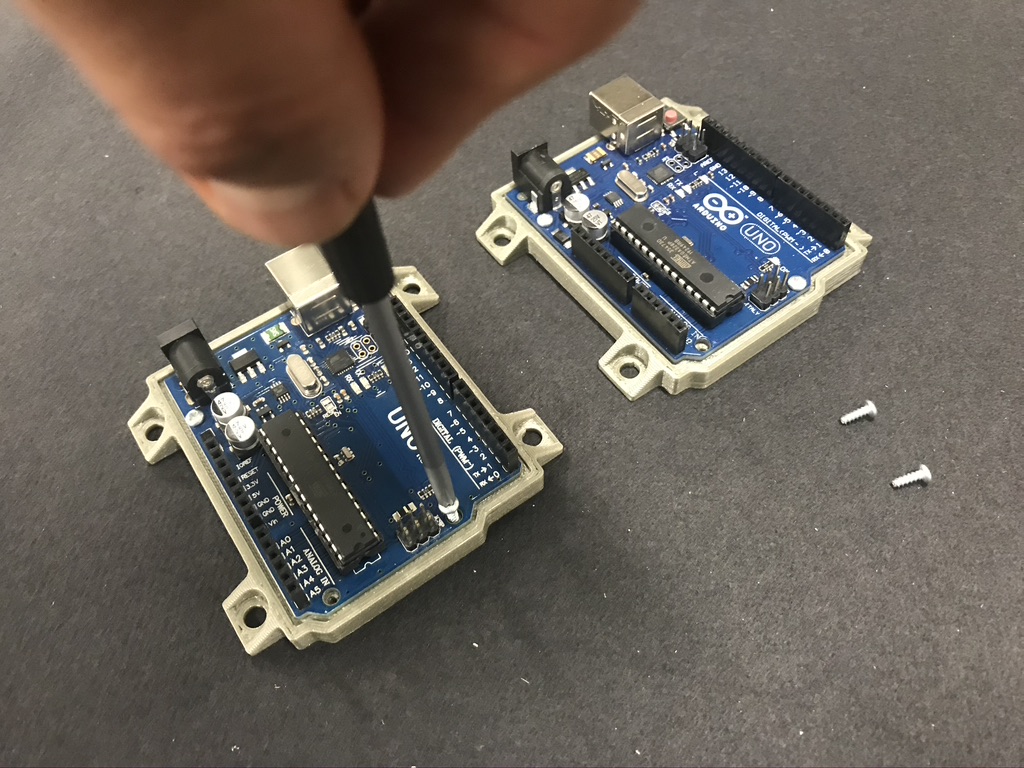

Servo City goBilda - Arduino (2x) - Arduino Uno (A000066)

Amazon AdaFruit - Wires - 22 AWG

- Power Supply - 7.5V (Model #vBK-UA-36)

Amazon - Linear Gear (2x) - 20 Degree Pressure Angle Gear Rack, 32 Pitch (2662N53)

McMaster - Gear (2x) - 32P, H23T Output Spline Servo Mount Gears (Metal) 32 Tooth (sku#615310)

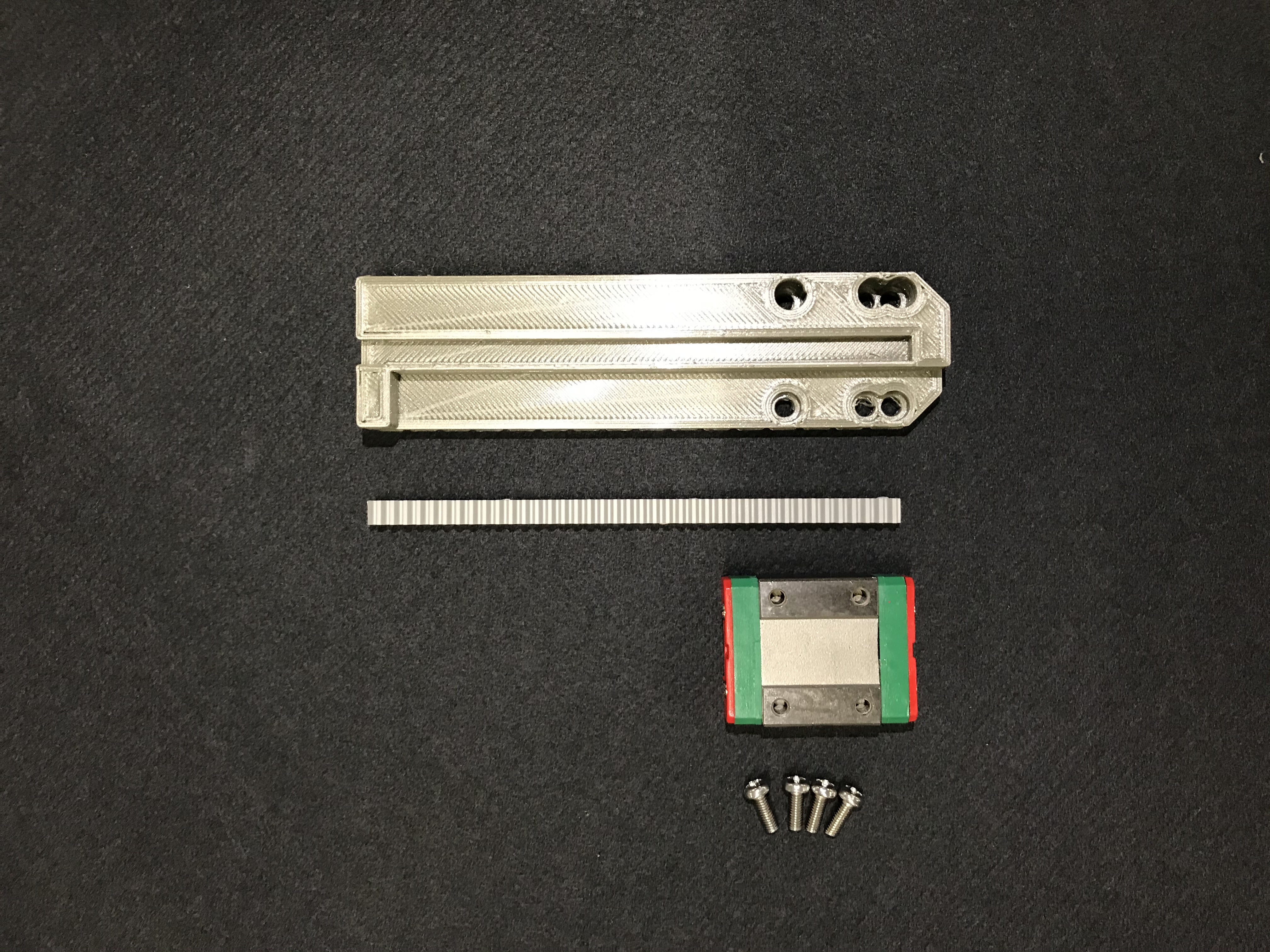

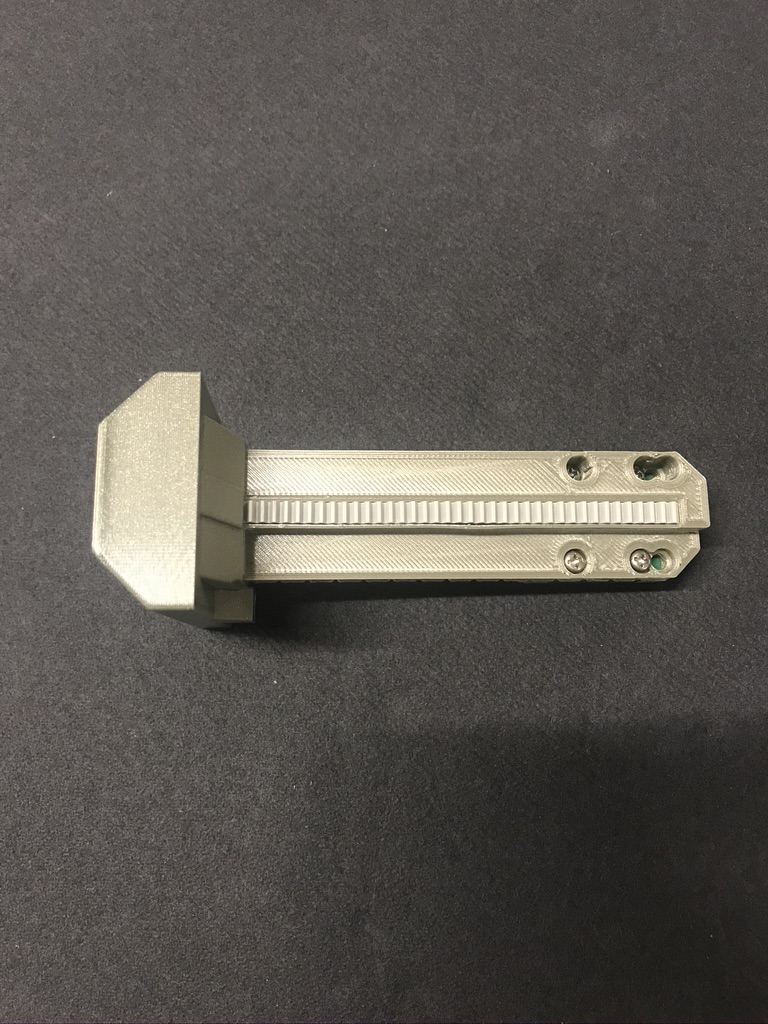

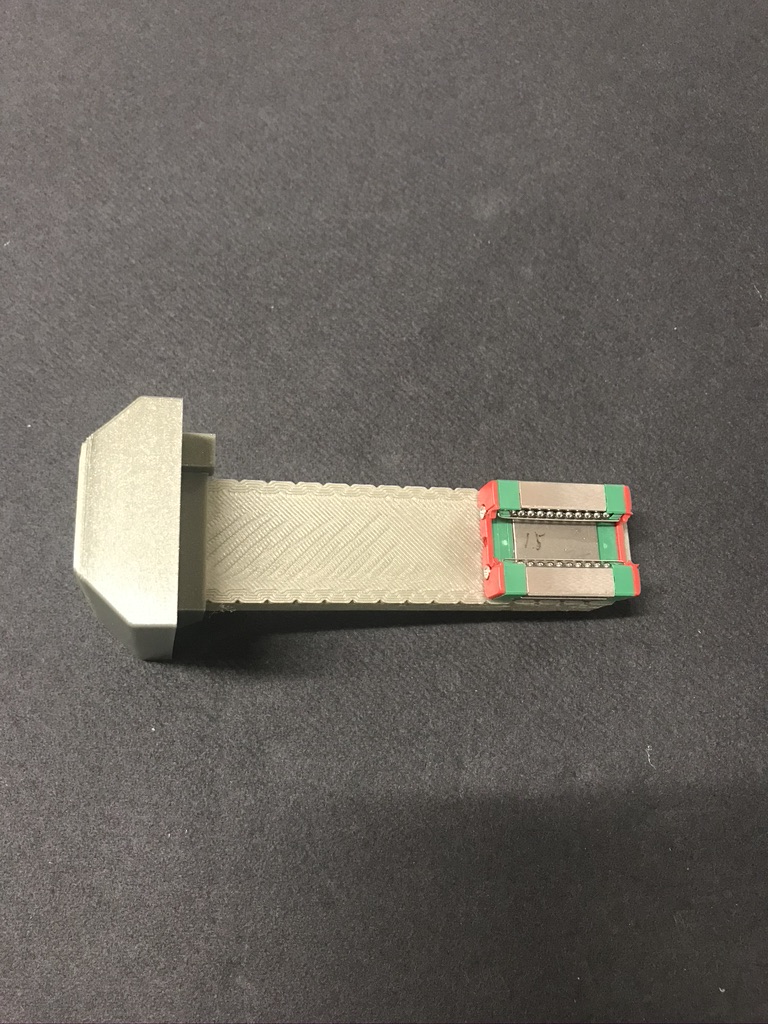

Servo City - Linear Bearing Rail with slider (2x) - MGN12 - 120mm (or longer but cut to 120mm)

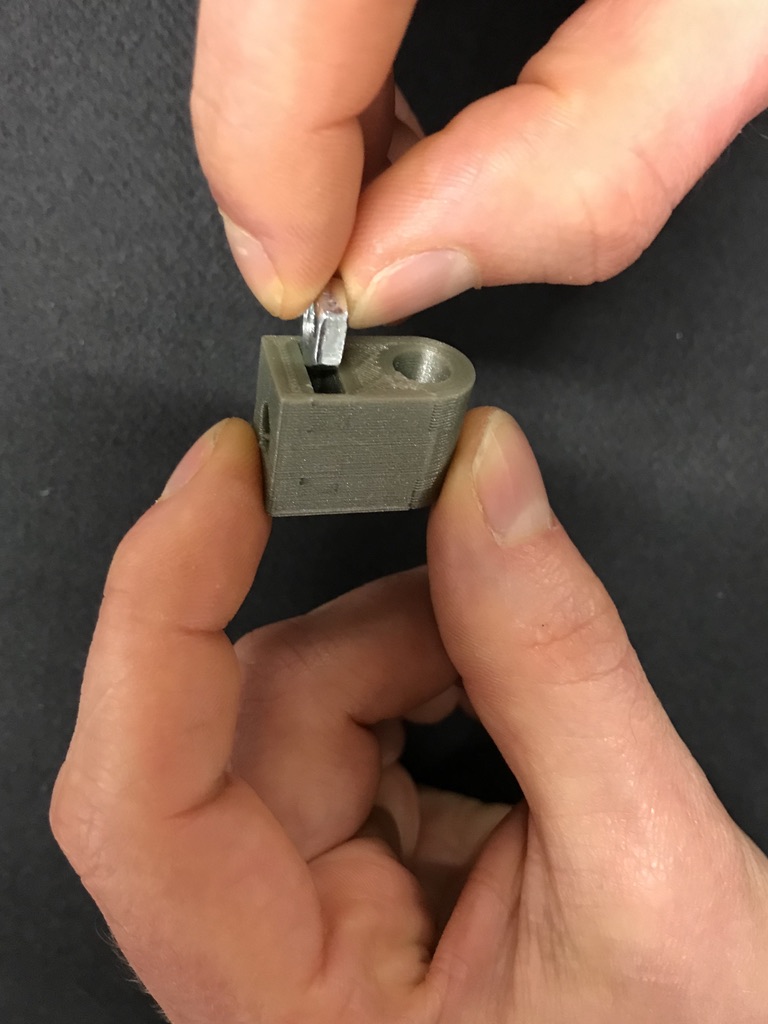

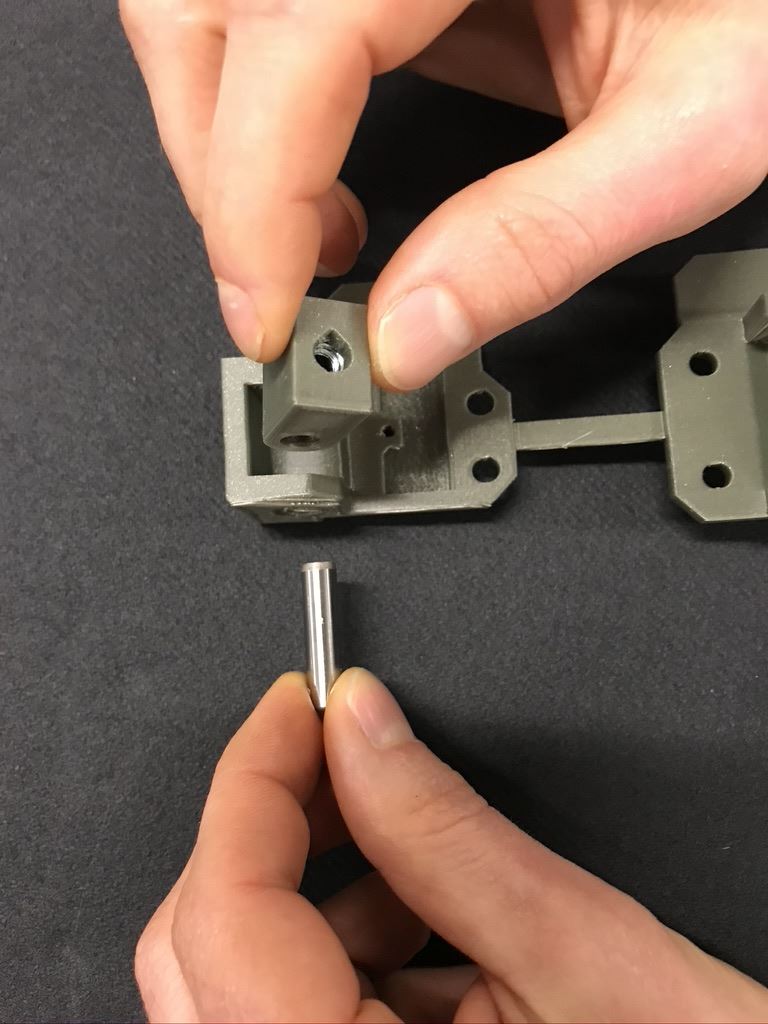

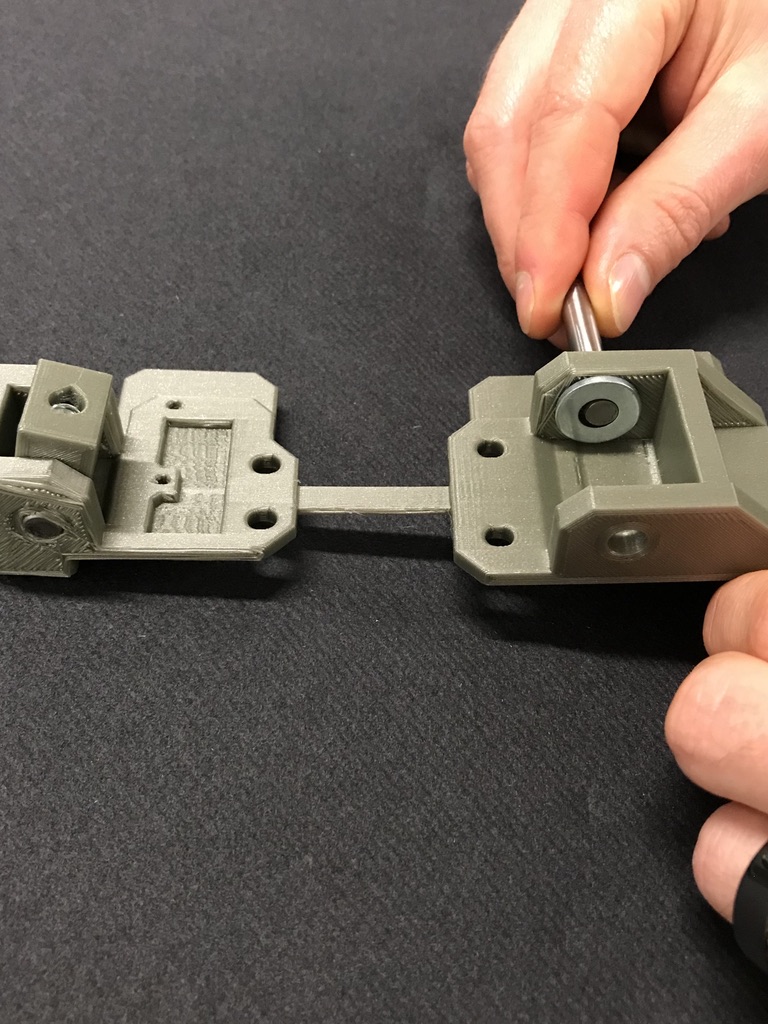

Aliaba Robot Digg - 1/4” Shaft (2x) - Dowel Pin, 1/4"x1" Long (98381A542)

McMaster - 1/4” Shaft (2x) - Dowel Pin, 1/4"x1-1/2" Long (98381A546)

McMaster - Spring (2x) - (P12-C029M16SQ64)

McMaster - Gear Tension Screw (2x) #10-24 x 1.5"

McMaster - Fasteners (36x) and washers (8x)

- Panel Mount 2.1mm DC barrel jack

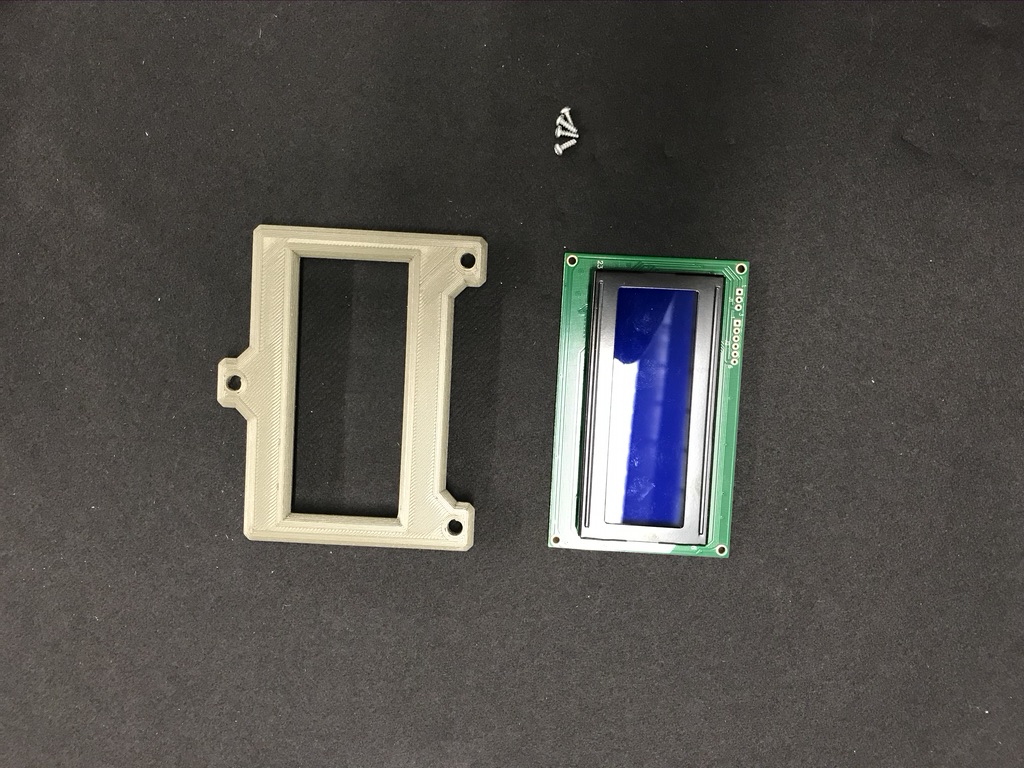

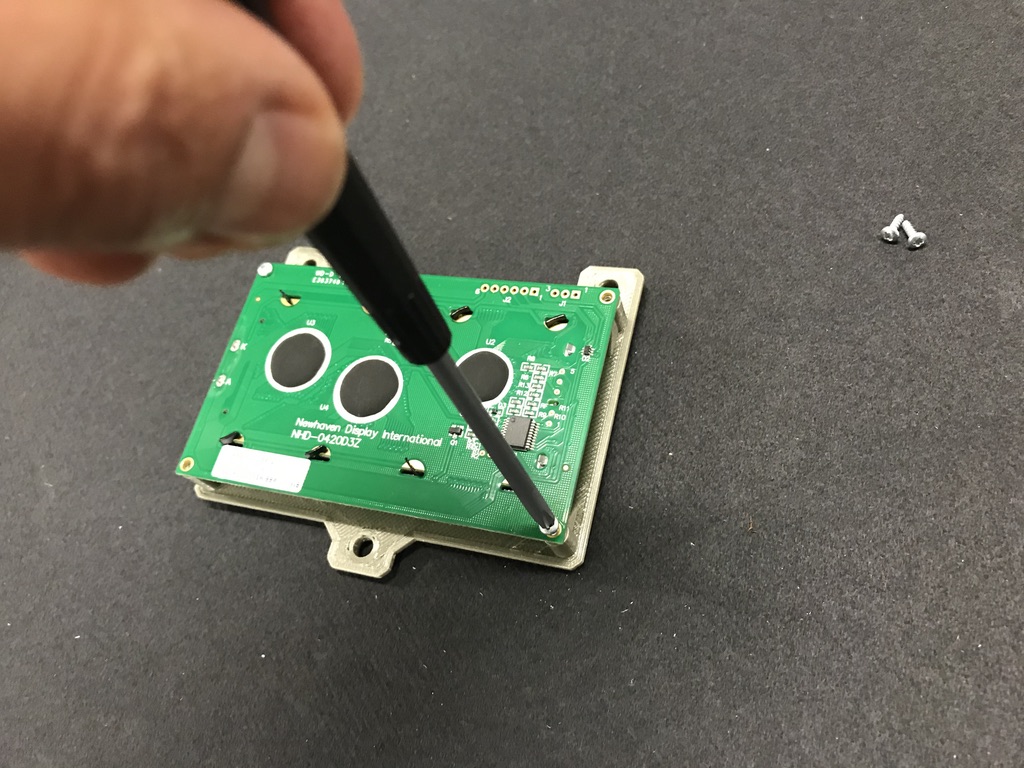

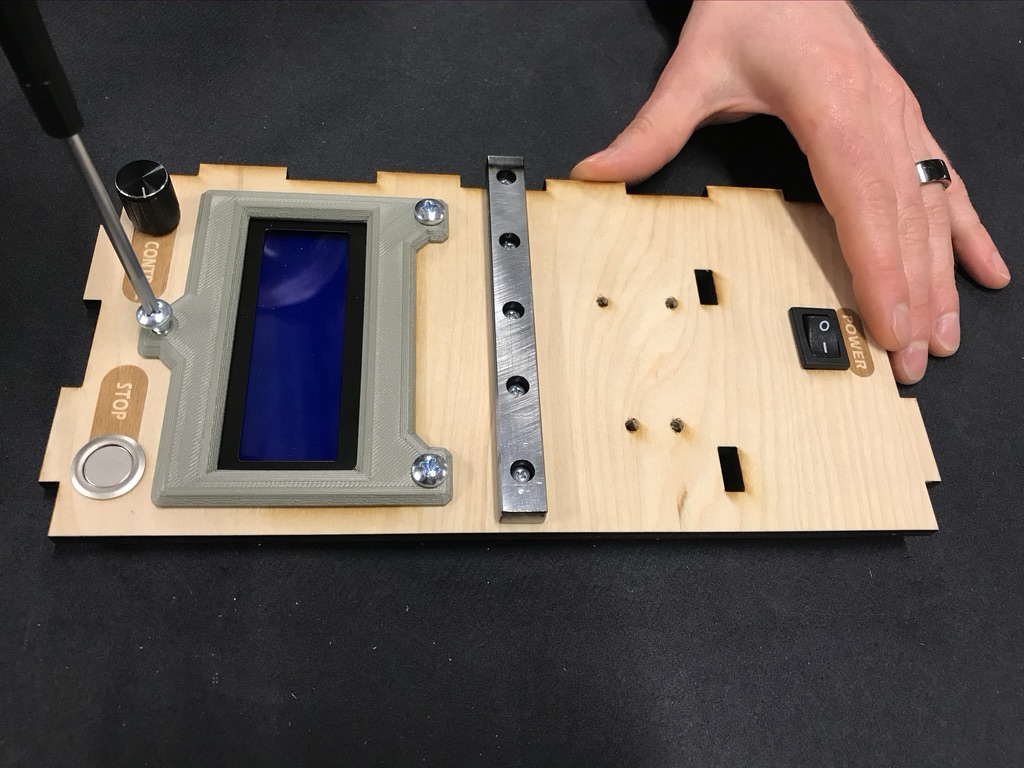

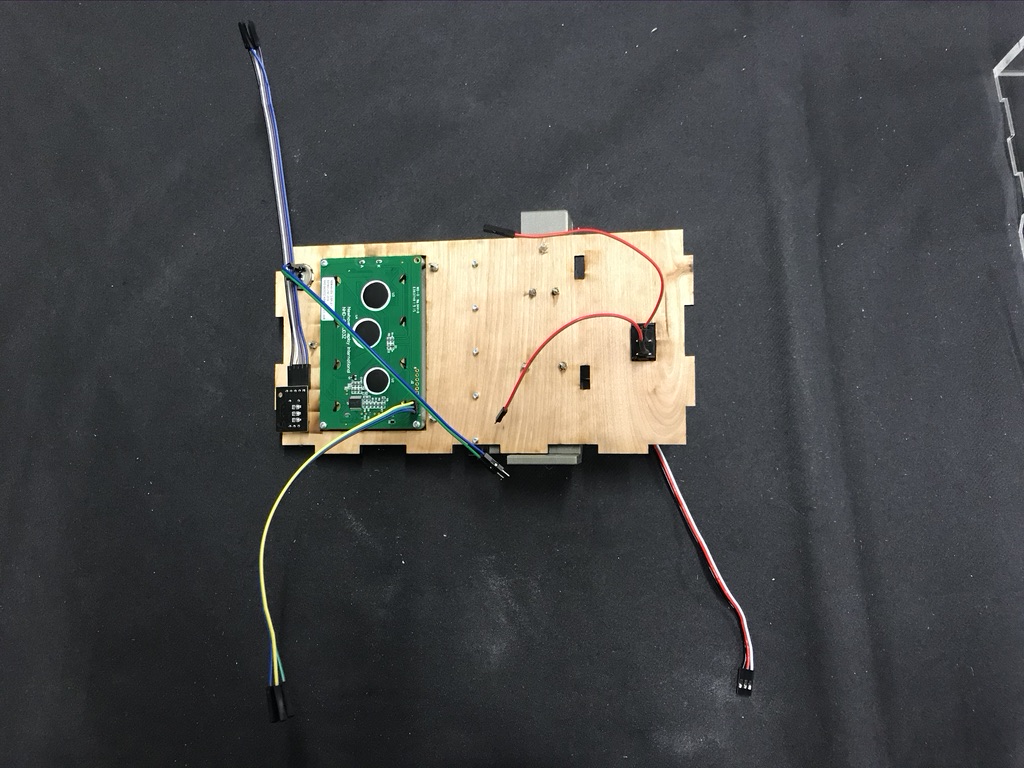

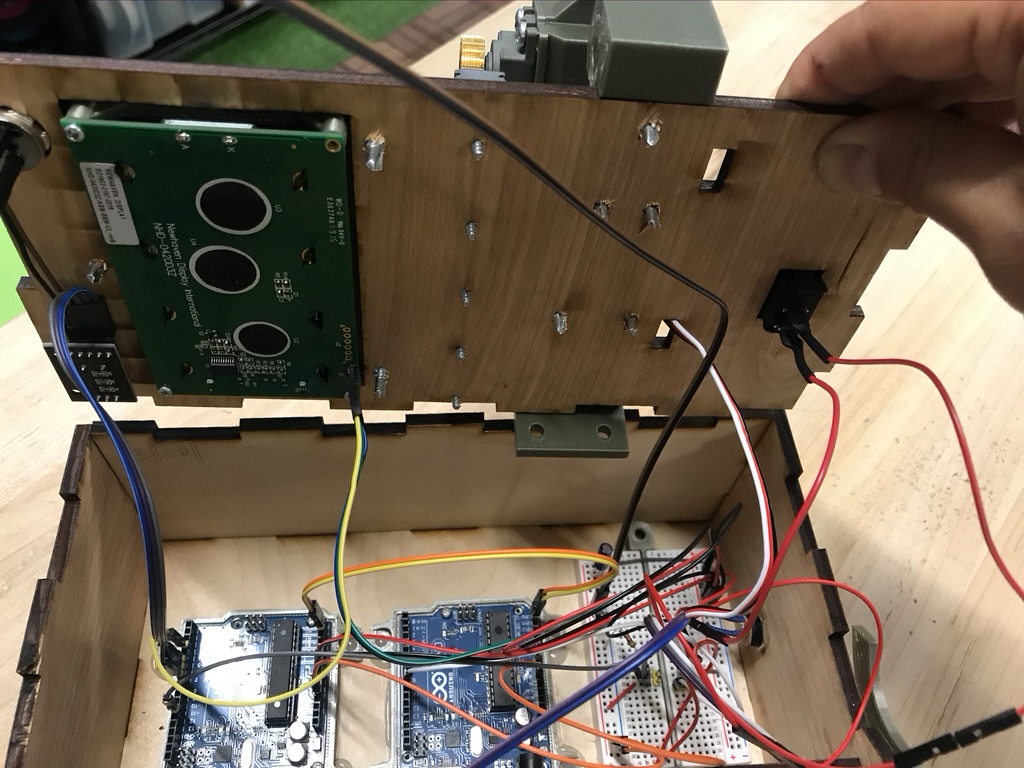

Mouser AdaFruit - Digital Screen - Serial 20x4 Liquid Crystal Display Module

Mouser - Metal Buttons (1x) - Push Button with 360 Degree Rotary Encoder (Part#WYTP23) (KY-040 Rotary Encoder)

Amazon Bangood - Push Button (1x) (3-109-081)

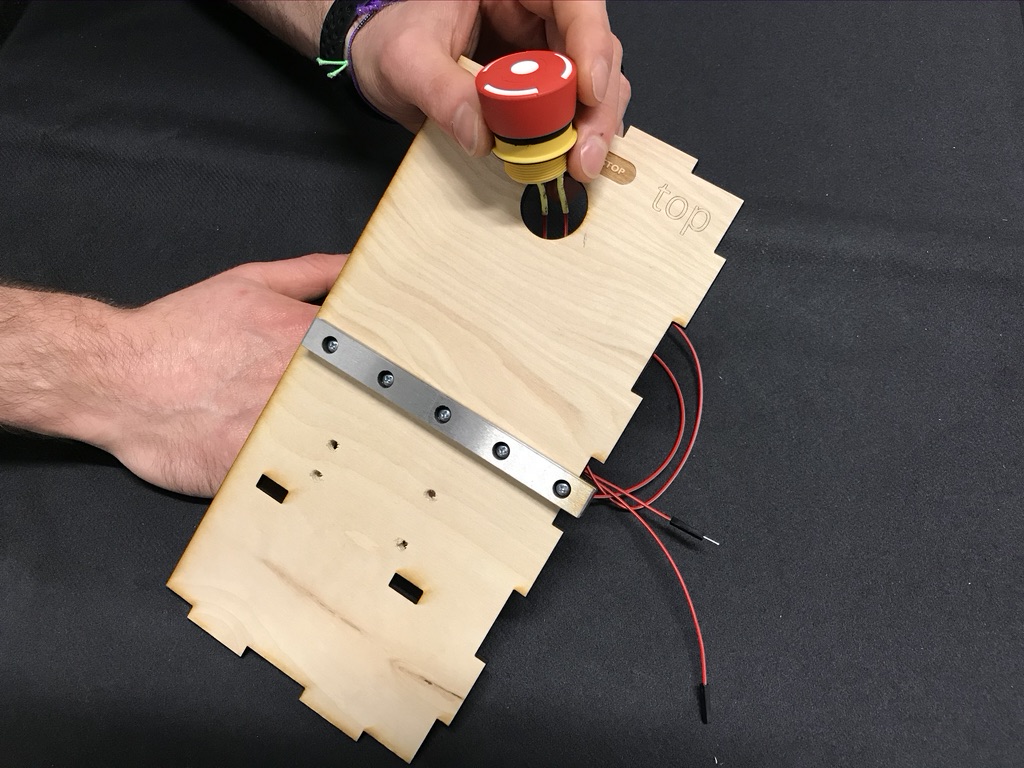

Mouser - Emergency Stop Button (84-5020.0020)

Mouser - Rocker Switch (RA11131121)

Mouser - PLA Filament

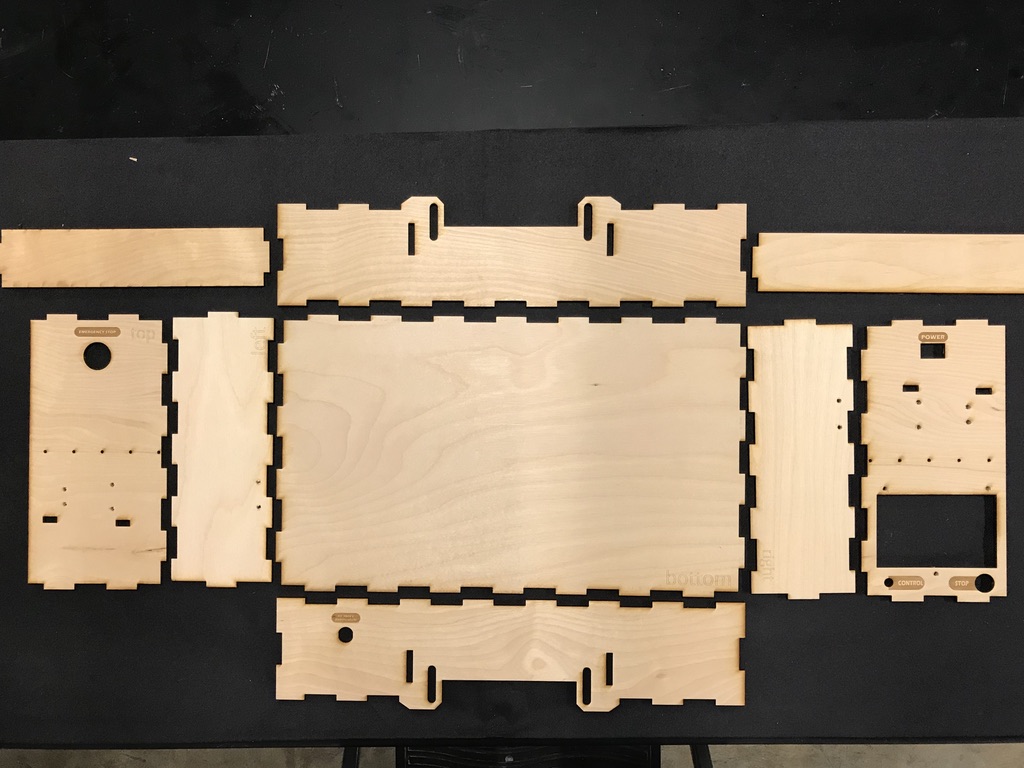

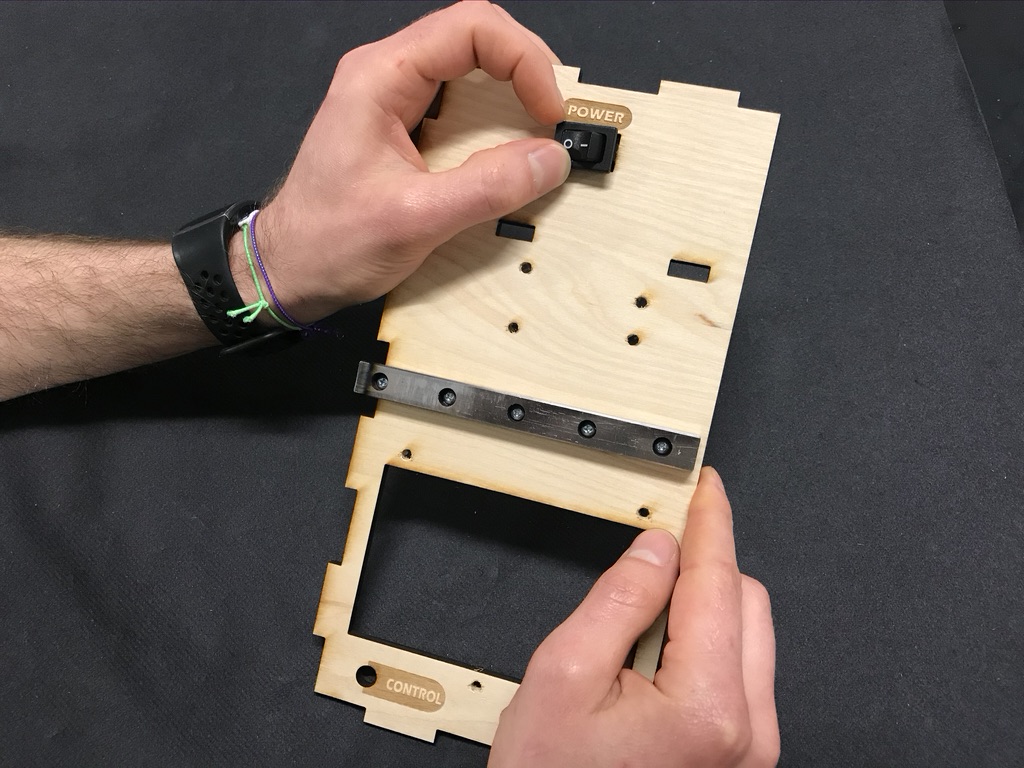

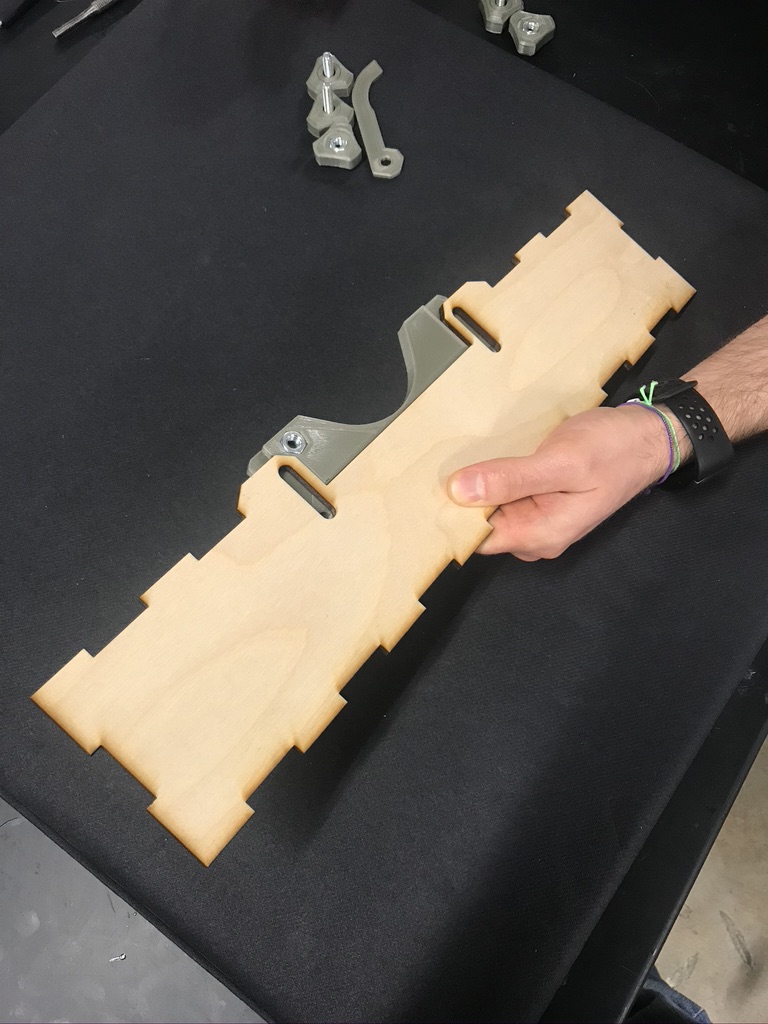

Prusament - 1/4 Birch Ply Sheet or plastic

- BVM with PEEP - AMBU Spur II

Ambu - ET endotracheal tube

Fasteners and Washers

| Item Description | Size | Quantity | McMaster-Carr P/N | LINK |

| Servo Mount Screws | #6 - ½” | 8 | 90380A148 | https://www.mcmaster.com/90380a148 |

| Linear Rail Screws | #8 - ⅜” | 10 | 90380A192 | https://www.mcmaster.com/90380a192 |

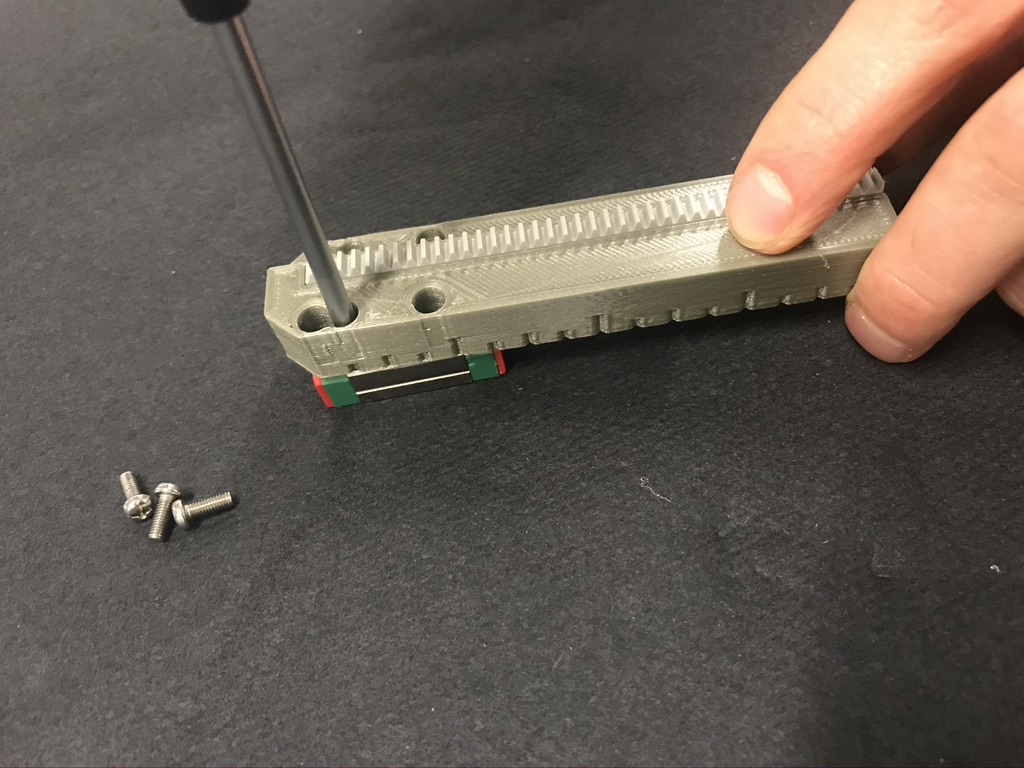

| Linear Bearing Screws* | M3 - 0.5 X 12mm | 8 | 92005A122 | https://www.mcmaster.com/92000a118 |

| Gear Screws | Note: comes with Servo motor | 2 | ||

| Motor Mount Washers | ¼” flat washer | 4 | 92141A029 | https://www.mcmaster.com/92141a029 |

| Motor Mount Screws** | #10 - 1” | 14 | 90380A240 | https://www.mcmaster.com/94060a247 |

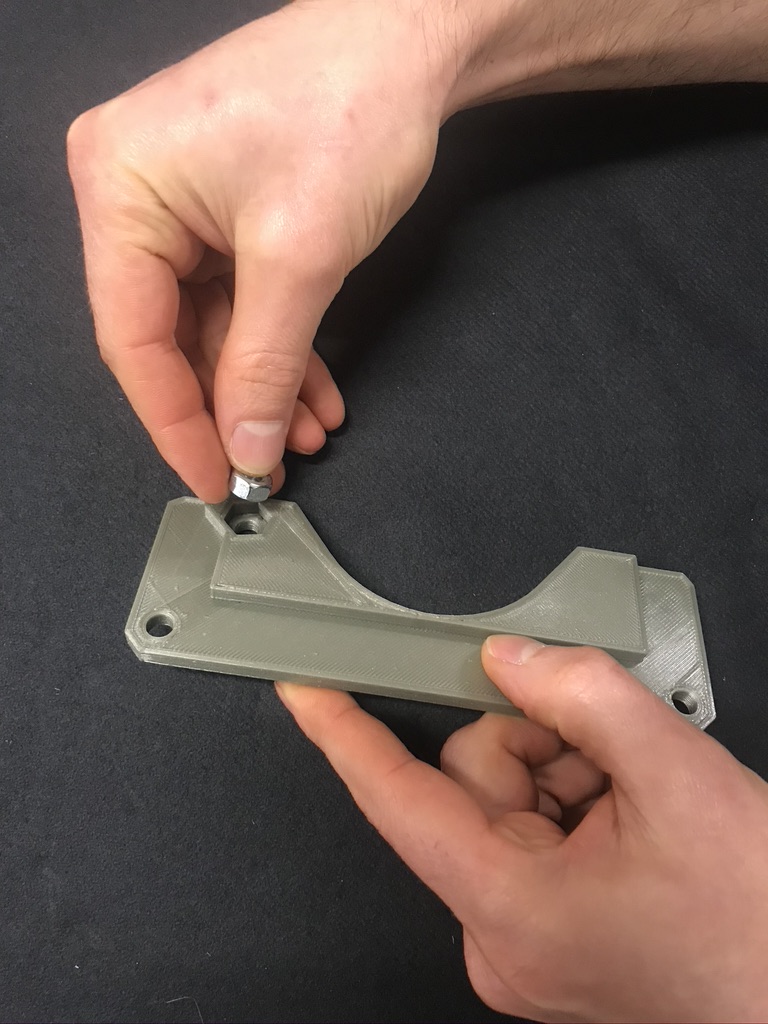

| BVM Hold Down Nuts | ¼”-20 hex nut | 6 | 95462A029 | https://www.mcmaster.com/95462a029 |

| BVM Hold Down Screws | ¼” - 20 x 1” hex head cap screws | 6 | 92865A542 | https://www.mcmaster.com/92865a542 |

| Screen Mount Screws | #2 - 1/4" | 4 | 90380A005 | https://www.mcmaster.com/90380a005 |

| Screen Mount Screws | #10 - 1" | 3 | 90380A251 | https://www.mcmaster.com/94060a247 |

| Spring Tension Screw | 10-32 x 1-1/2" | 2 | 92196A277 | https://www.mcmaster.com/92196a277 |

| Spring Base Nut | 10-32 hex nut | 2 | 90480A195 | https://www.mcmaster.com/90480a195 |

*Note: Changed screw size from M2 to M3

**Note: Changed screw size from #10-14 x 3/4 to #10-1"

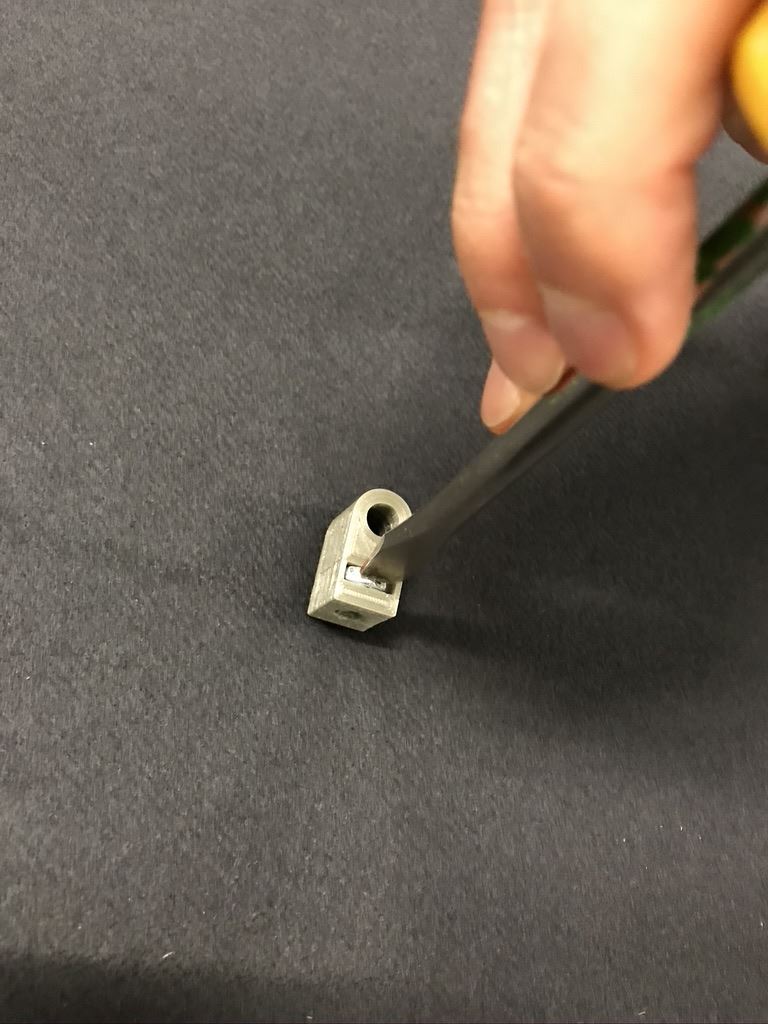

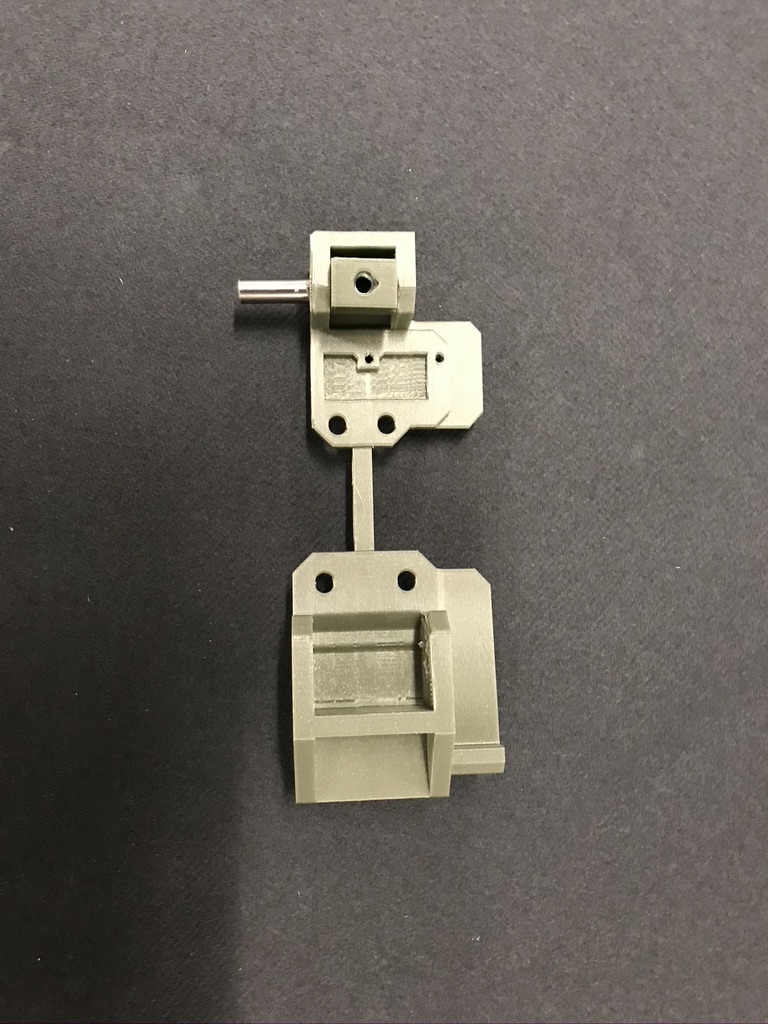

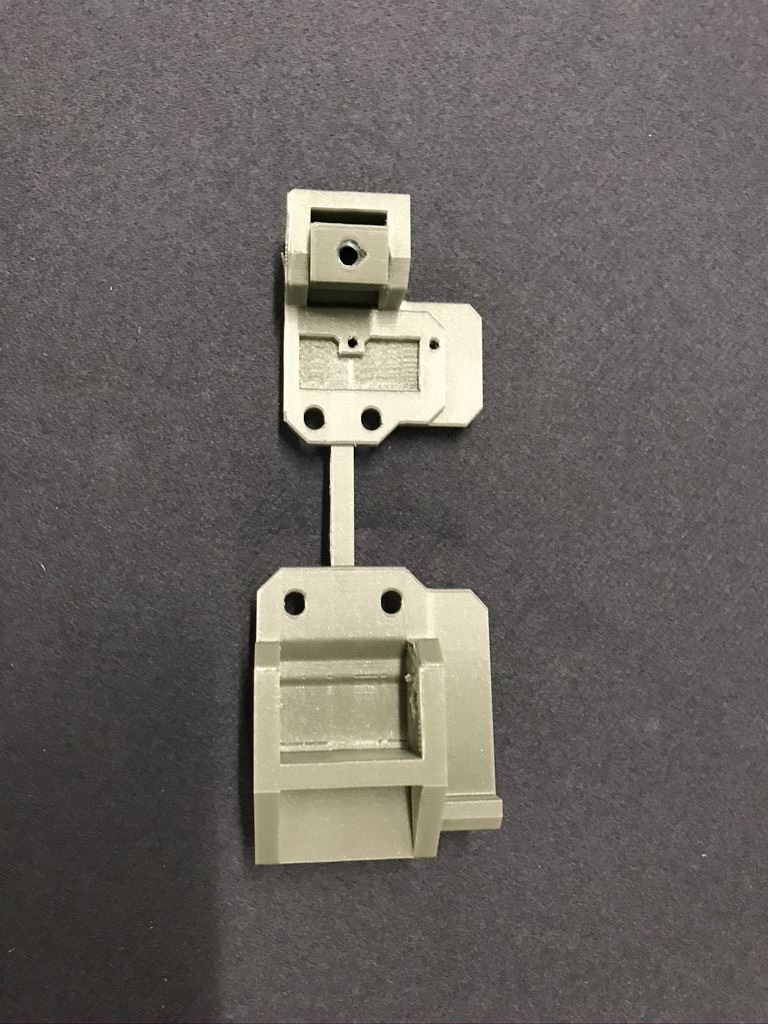

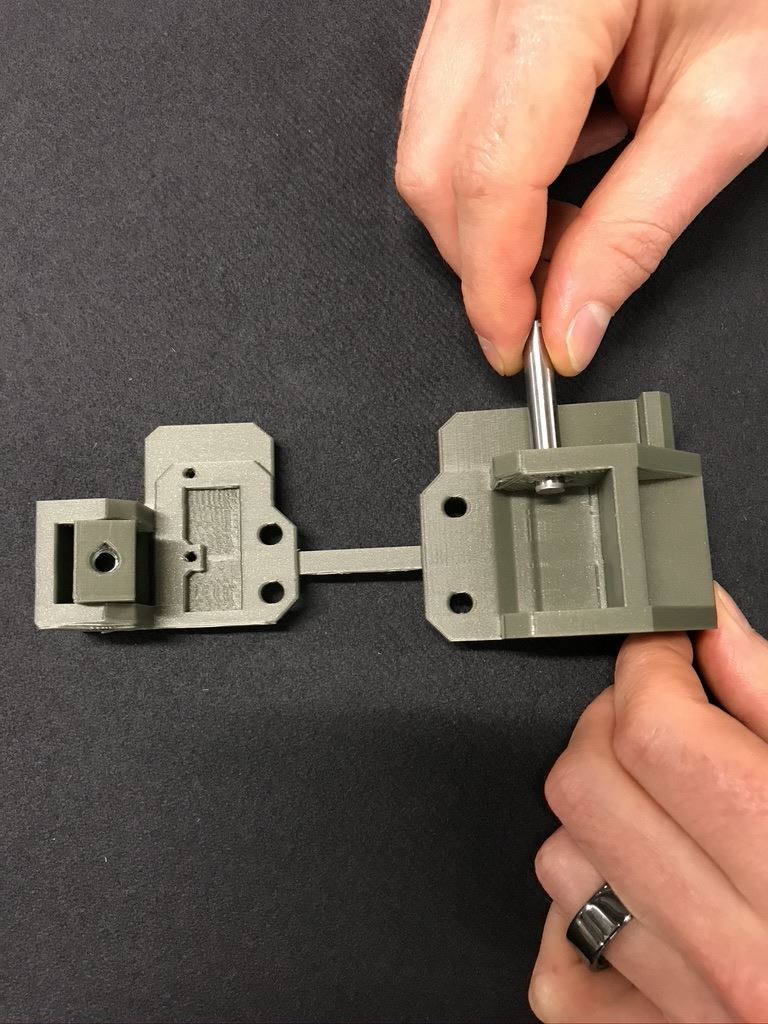

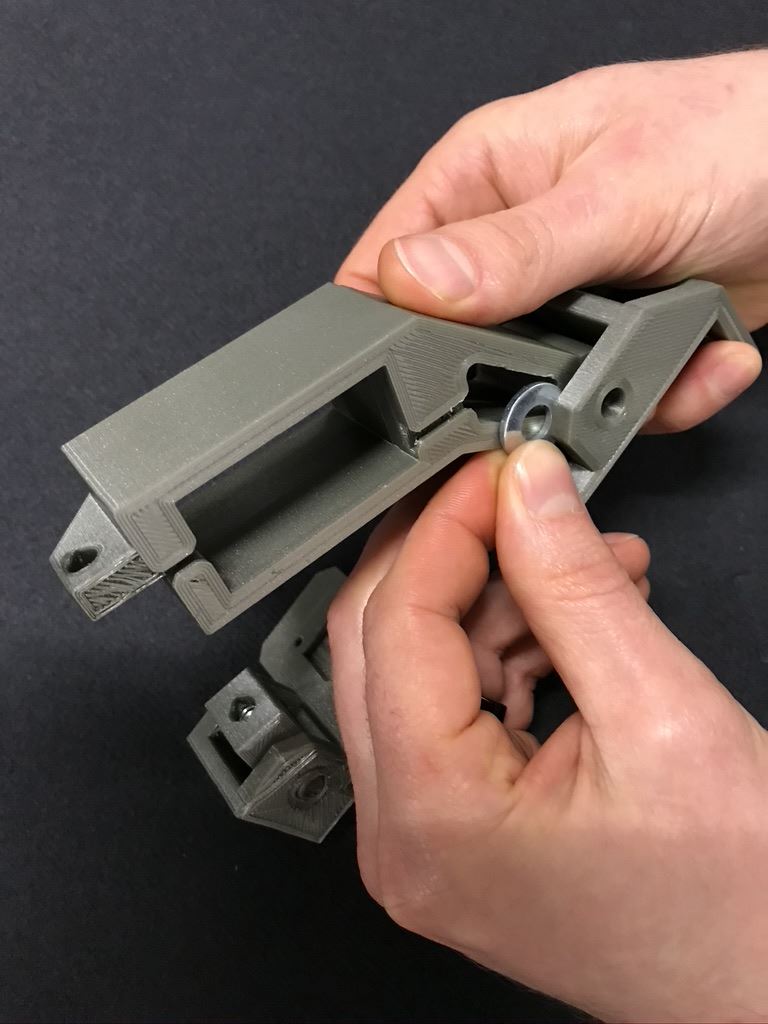

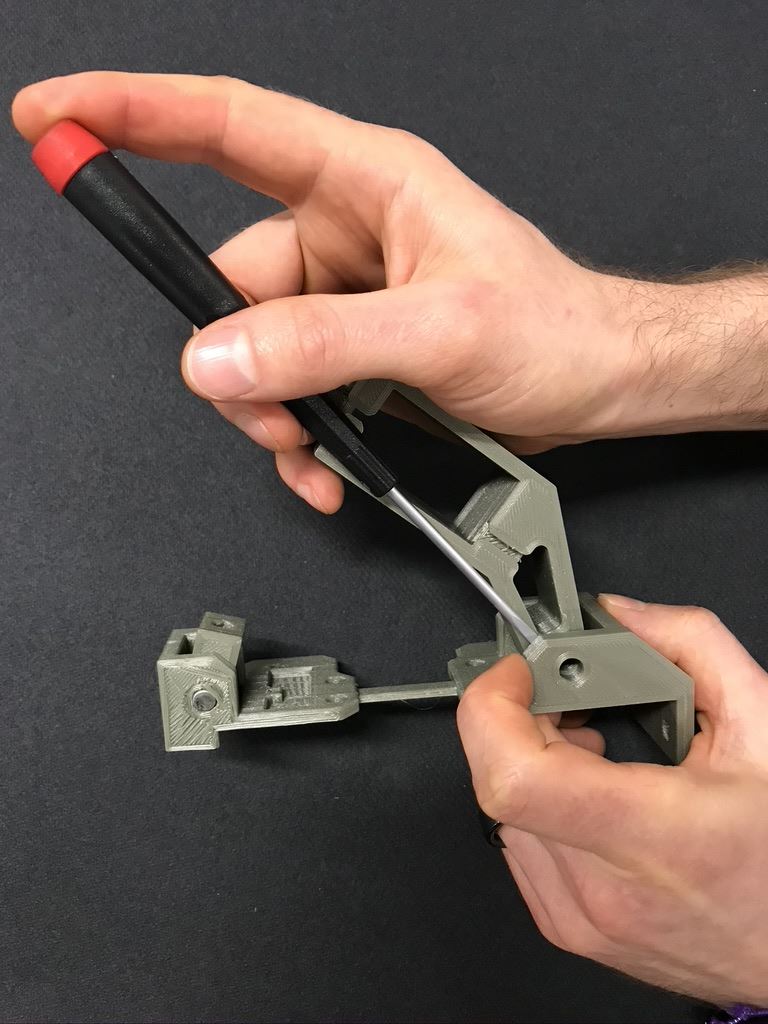

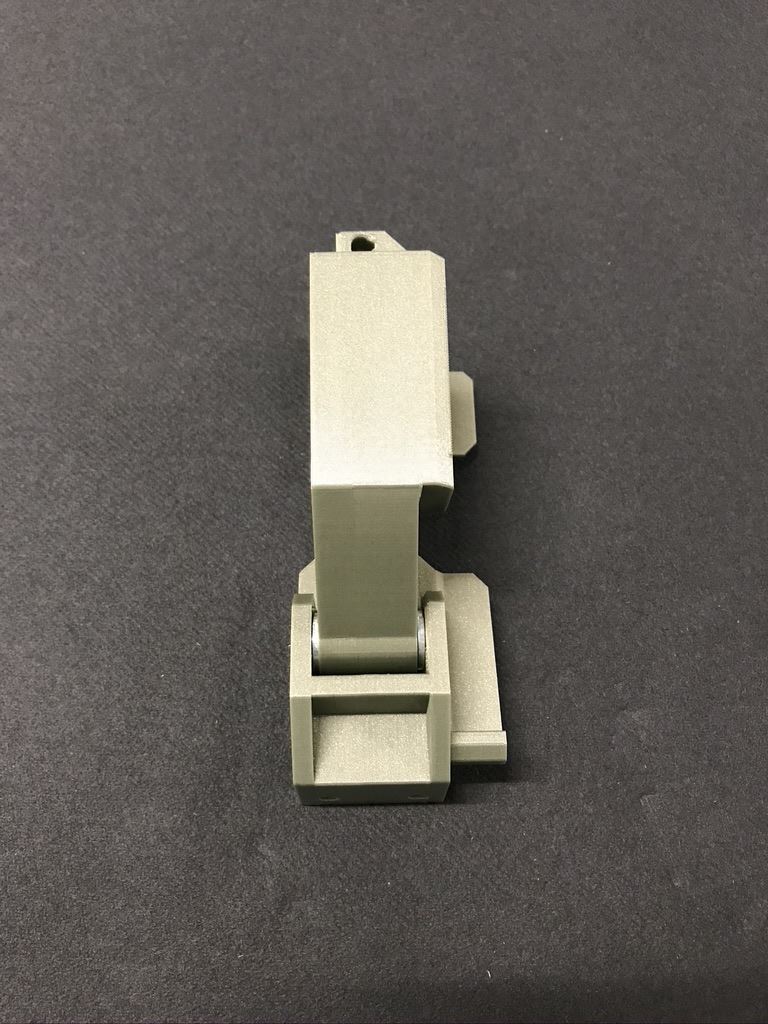

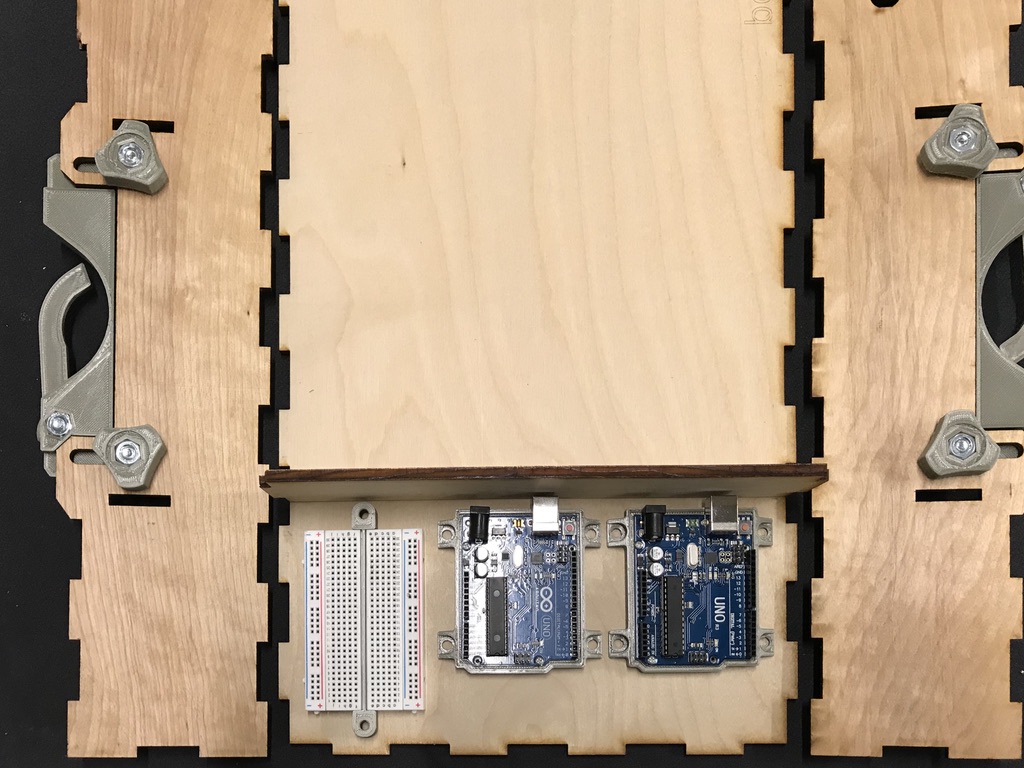

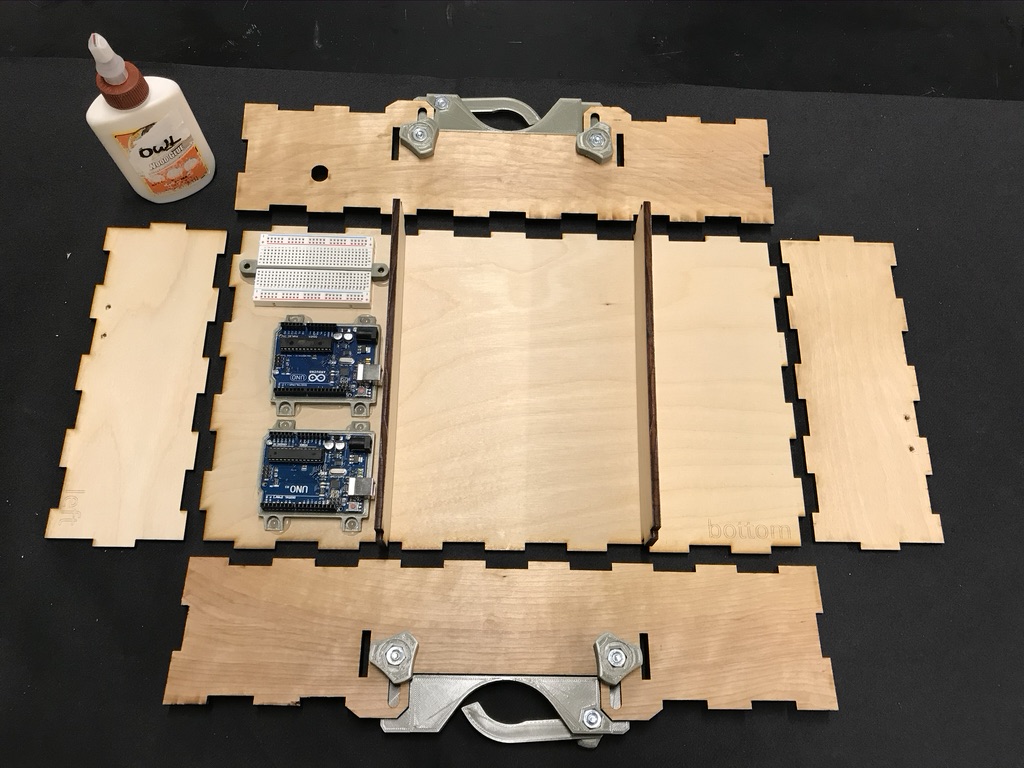

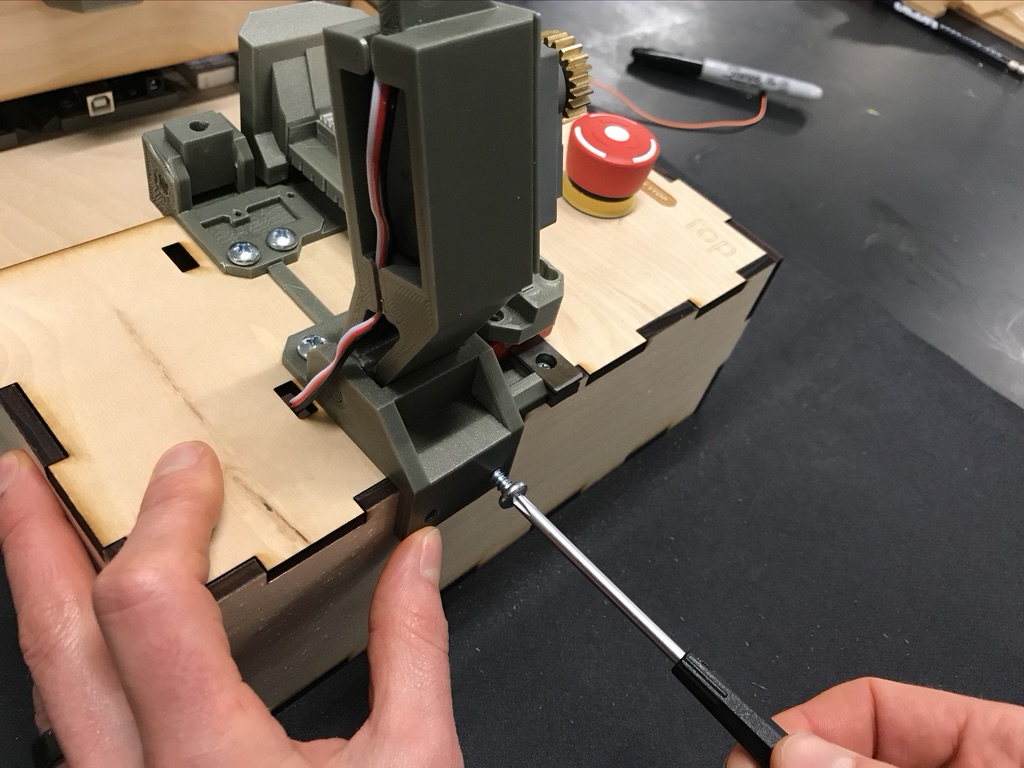

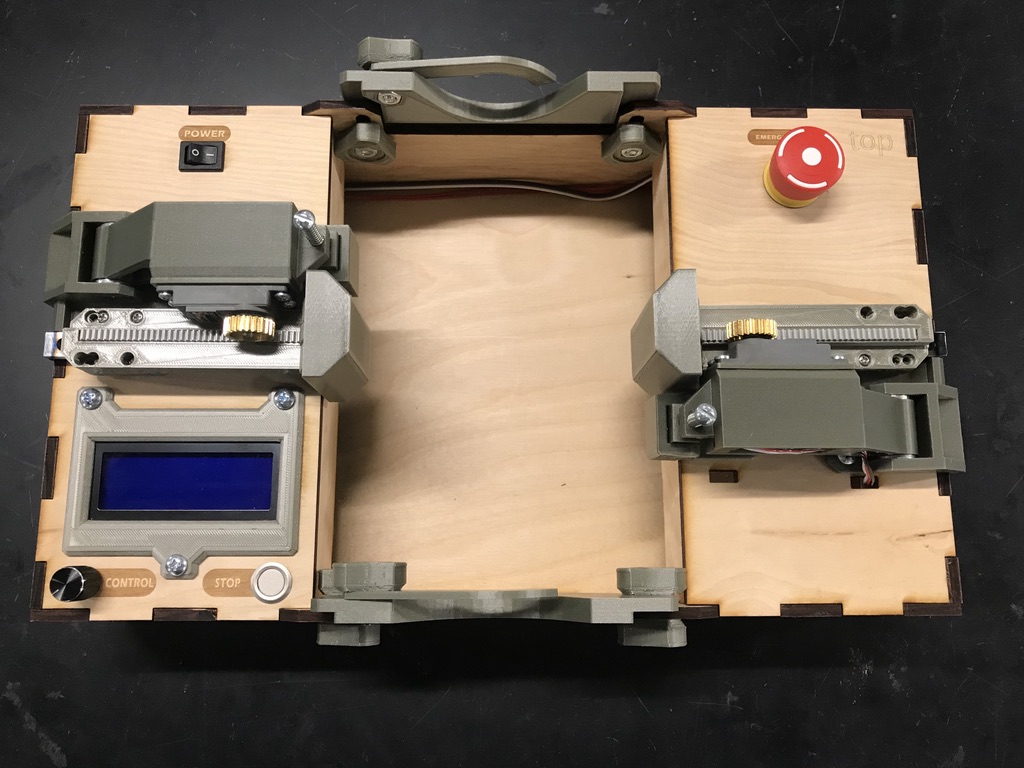

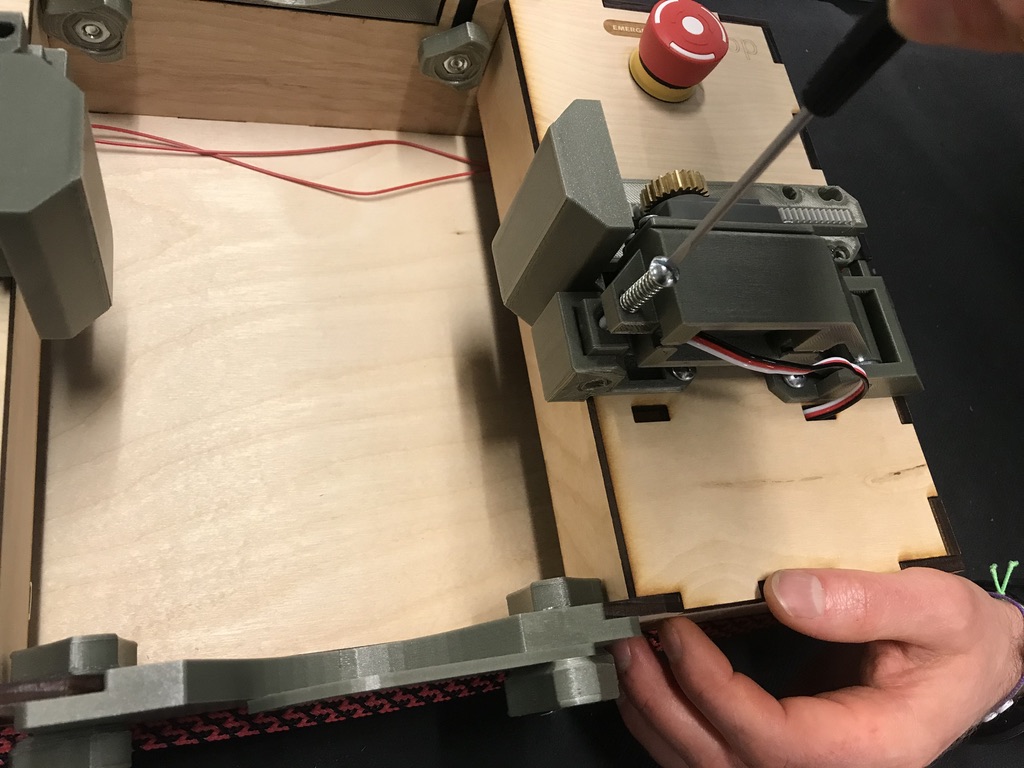

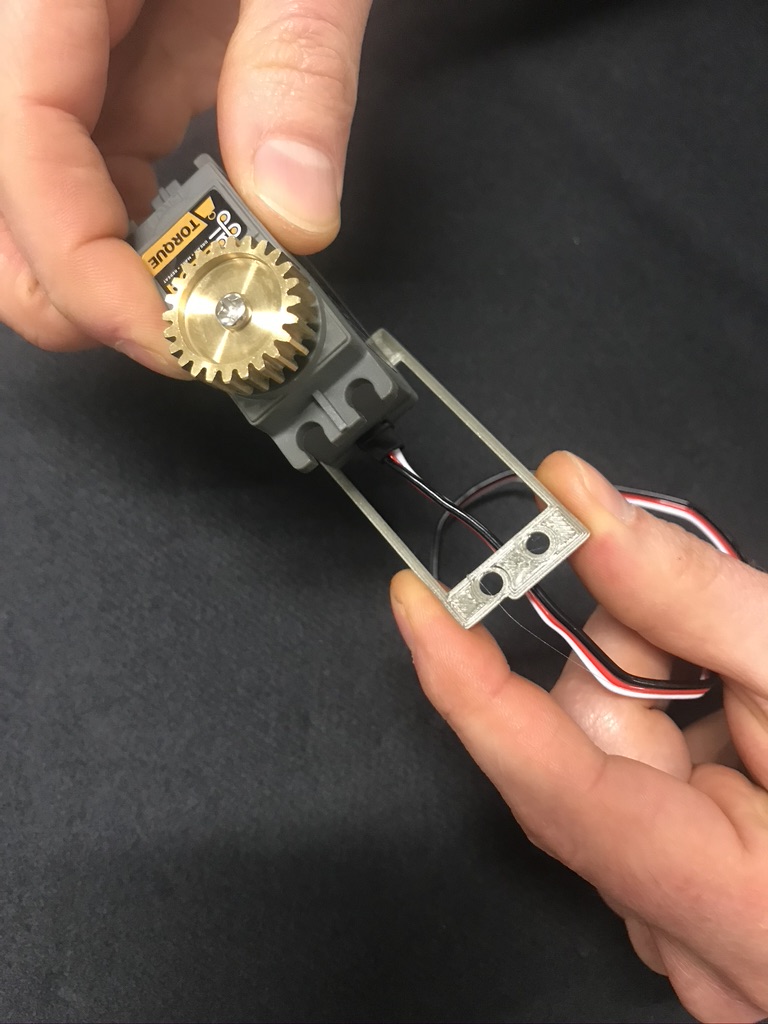

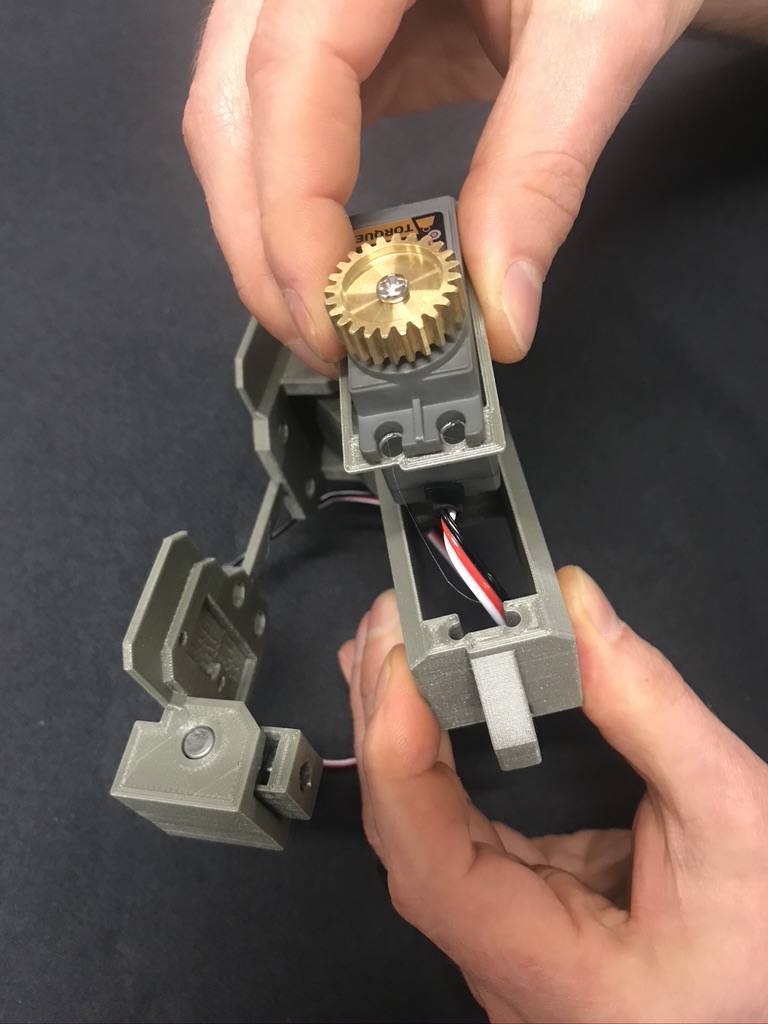

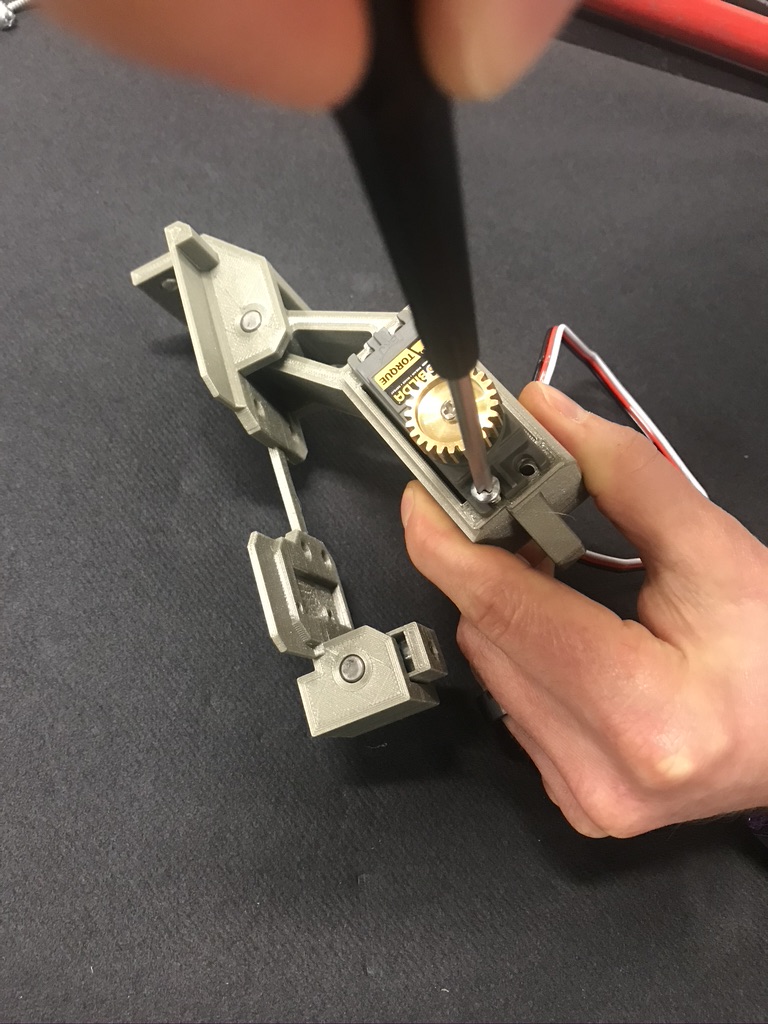

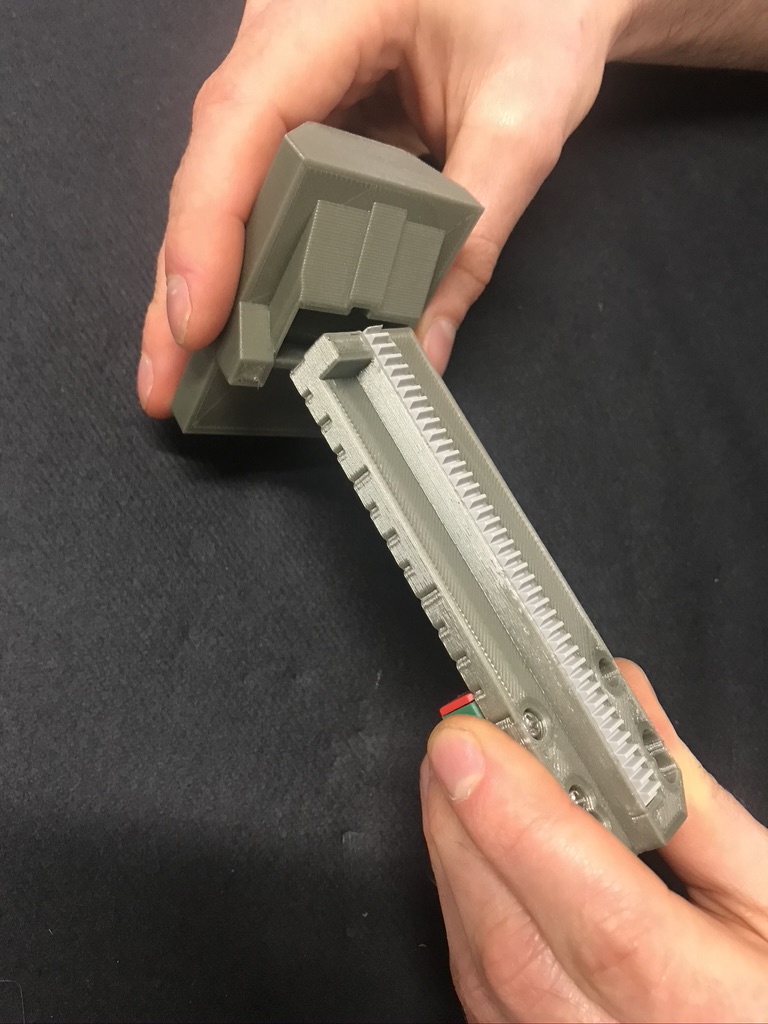

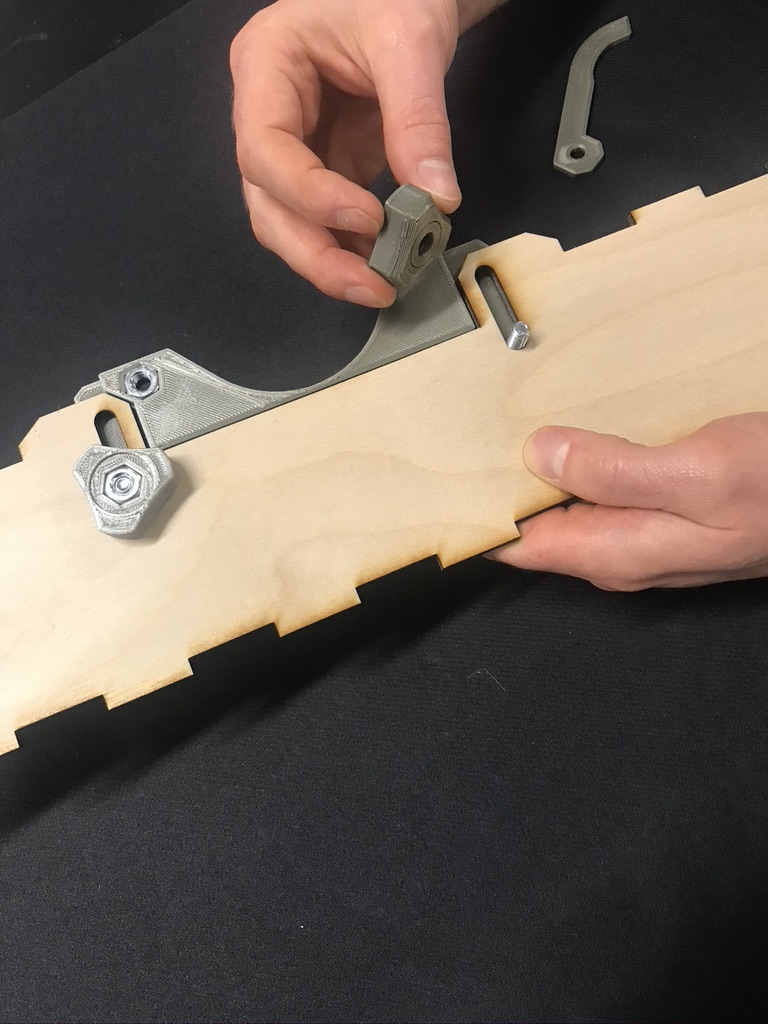

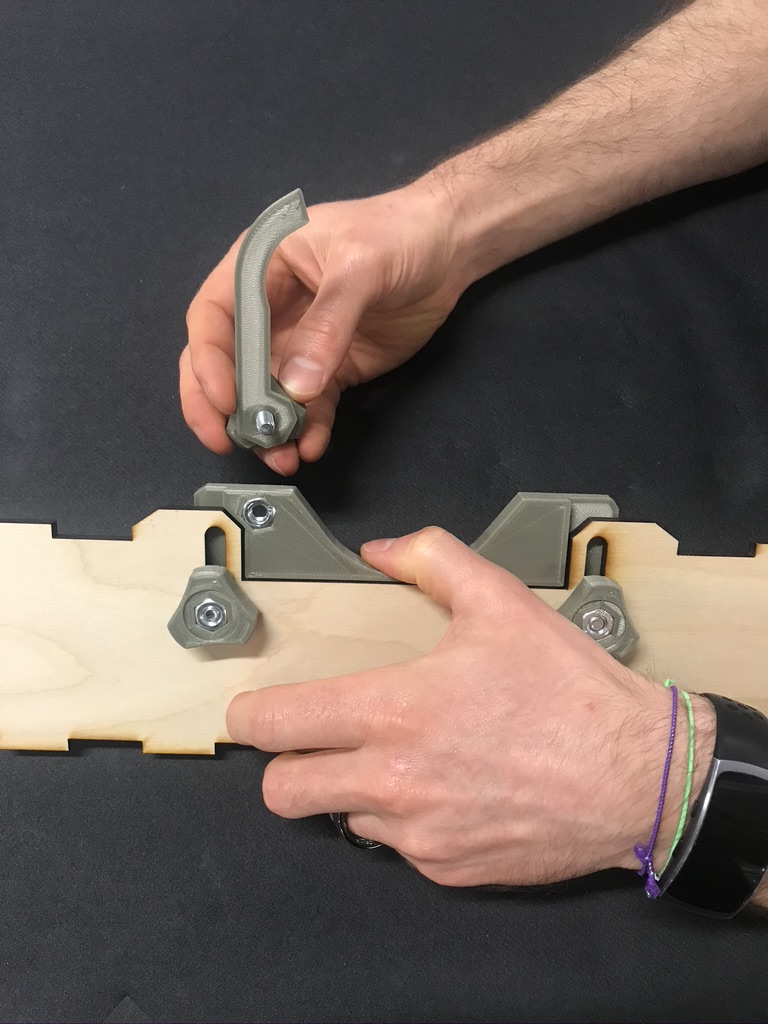

The motor mounts is mostly 3D printed parts. Each side consists of five 3D printed parts which will be put together with fasteners and dowels. The motor should easily fit into the motor mount. Motor assembly is below. You will need to make 2 of these for the finished design. |

.png)

Power on device and install software. |

Push gear rack assembly back until it stops. Lower servo mount arm. Insert (1) 10-24 x 1-1/2" bolt inside 1" spring and secure to spring base. |

You will need to make 2 of these for the finished design.

You will need to make 2 of these for the finished design.

|

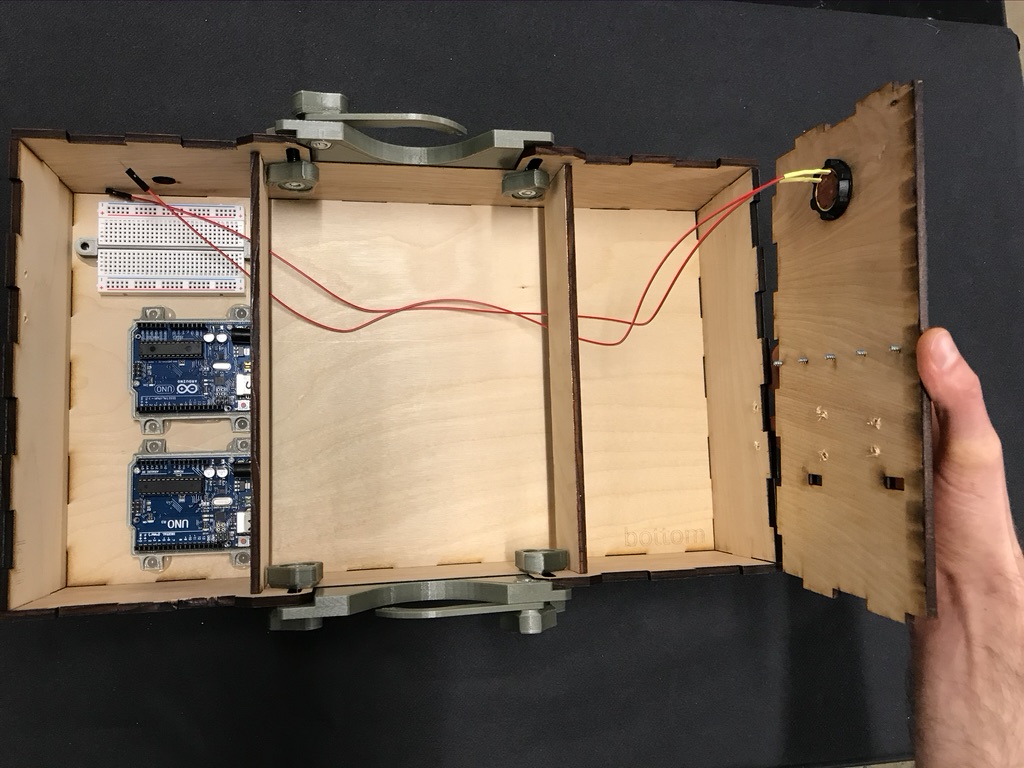

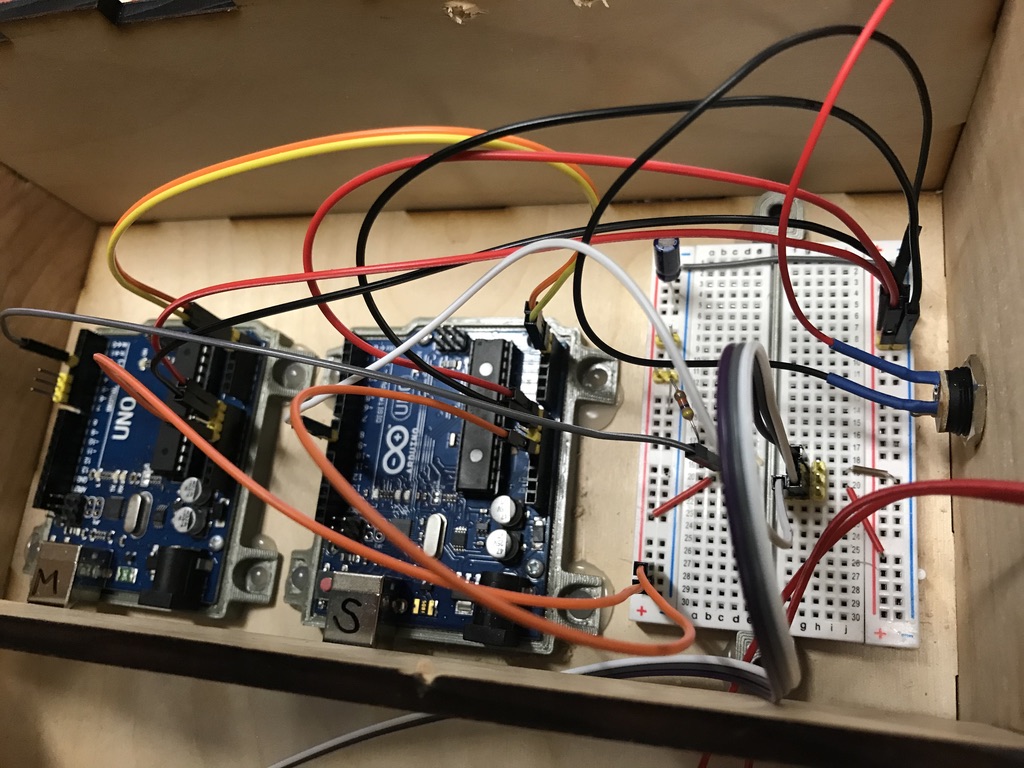

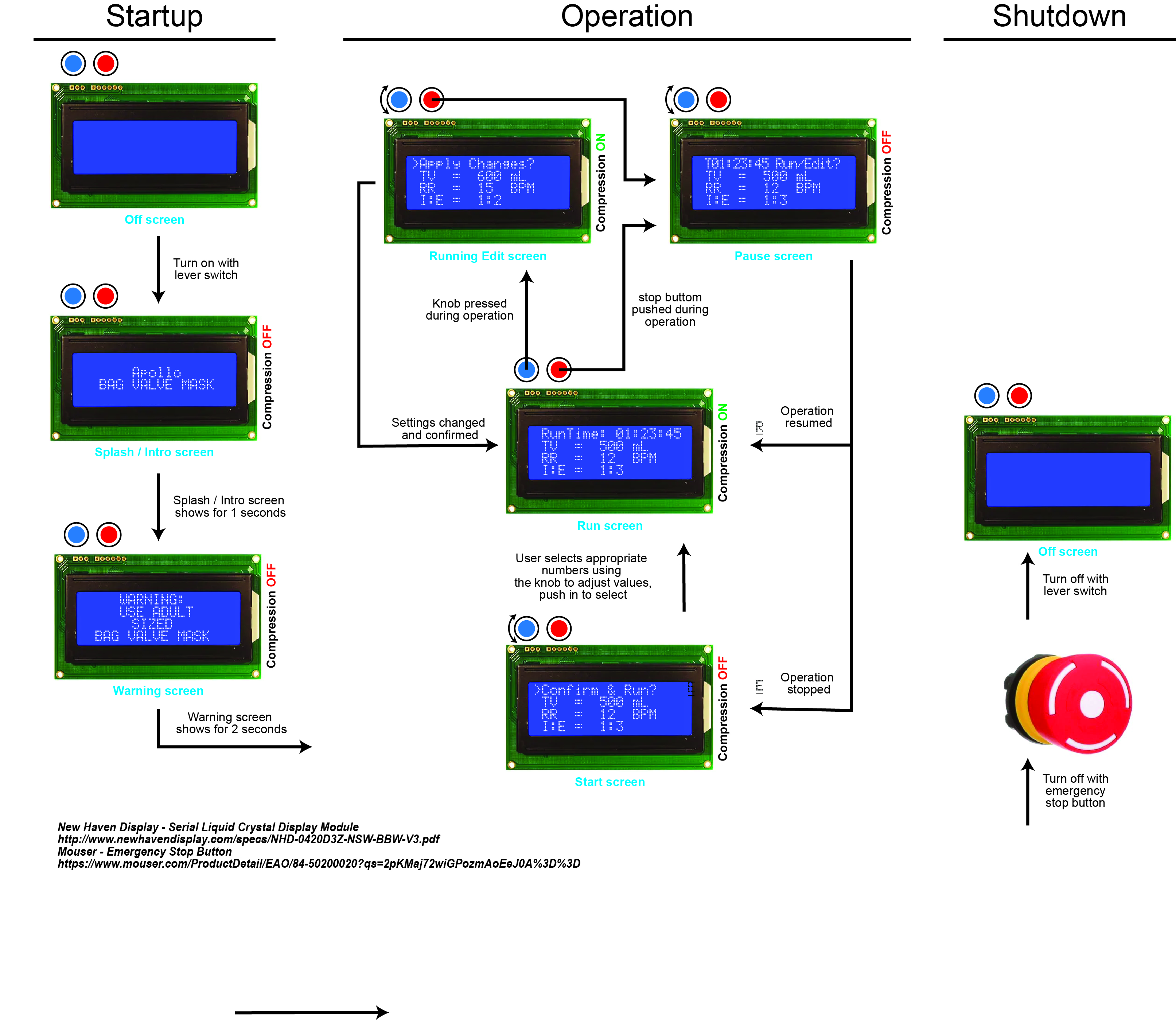

The ApolloBVM system uses two coordinated microcontrollers in order to facilitate user input while guaranteeing uninterrupted airflow. The system has a master controller, responsible for managing the display and user input, and a slave controller that actually sends motor commands to the servos. This allows the master controller to operate entirely separately from the slave and ensures that the system is real-time safe. In order to give more clarity about the technical operation of this device, we will outline the operation of each controller separately.

In order to facilitate the various functions of the device, the slave controller operates in 3 distinct states: load, on, and off. While in the ‘load’ state, the slave controller will read ventilation parameters from the master over the I2C bus, generate a new trajectory with these parameters, and turn its state to ‘on’. While in the ‘on’ state, the device will follow the trajectory over and over for infinity. This means that the slave controller will never stop moving the motors unless it receives a command from the master to change its state to ‘stop’. If the master controller were to do so, the device would finish its current cycle and stop moving.

The master controller is mainly tasked with running the user display and sending commands to the slave. Internally, the master switches which panel is currently displaying and manages input from the encoder and buttons. Each panel that the master displays is programmed to follow a different behavior and is modular. This makes it easy to implement panels that behave completely differently and interact with the slave controller on the fly.

For implementation details, please refer to the Github repository where we documented source code.

Set up of Ventilation Parameters

All ventilation parameters must be set by the clinical provider caring for the patient. It is suggested to have the patient sedated with neuromuscular blockade for the acute phase of respiratory support. This may be followed by titrated sedation to a RASS score of -2. All patients should be continuously monitored during mechanical ventilation to include pulse oxygenation and also ideally continuous capnometry (end-tidal carbon dioxide -- ETCO2).

The minimum controllable parameters in order to ventilate a patient on ApolloBVM include:

| Parameter | Range | Default |

| Respiratory Rate (breaths/min) | 5-30 | 12 |

| VT (Tidal volume in cc, set at 6-8 cc/kg of ideal body weight) | 300-650 | 500 |

| I:E (Inspiratory time/Expiratory time per cycle) | 1:2 to 1:4 | 1:3 |

| PEEP (Positive end expiratory pressure in cmH20) | 5-20 | 8 |

PEEP Valve or Gauge

Most BVMs include a PEEP valve with an adjustable dial set for 20-40 cmH20. The purpose of this valve is to limit peak airway pressure to the number set on the dial. Ideally, peak airway pressure should be less than 40 cmH20. It will not be possible to measure PEEP with this valve.

Select BVM models include a PEEP valve with a gauge that ranges from 0-60 cmH20. These models allow for calibrated monitoring of PEEP during all portions of the breath cycle.

VT should be adjusted until the desired PEEP value is reached at the end of the breath cycle (8 cm H20 is a reasonable initial target).

With regard to ventilated COVID patients, it is quite likely that the desired PEEP will reach the 10-15 cmH20 range quickly.

Plateau Pressure

On an inspiratory hold of 0.5 seconds (at the end of the inspiratory portion of breath cycle), measured pressure should be <30 cmH20 to minimize ventilator-induced lung injury (VILI).

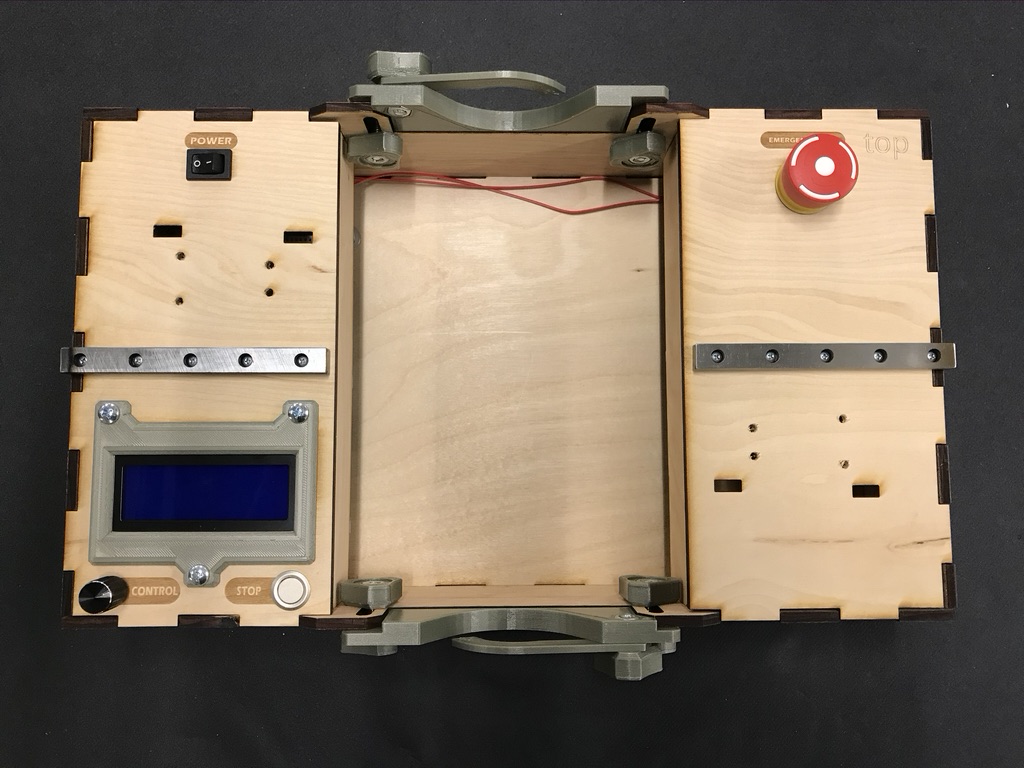

Emergency stop

There is an emergency shut-off button that turns off the device and allows for manual override and standard use of the BVM. (Version 1)

Supplemental Oxygenation

Most BVMs have a port to blend-in oxygen. Room air is 21% oxygen. Wall or tank-based oxygen is 100% oxygen. The higher the flow rate for ported-in oxygen, the higher the fractional percent of oxygen delivered to the patient. In acute ventilatory support, room air is often sufficient. Appropriate VT and PEEP are the keys to gas exchange.

Viral Filtration

HEPA filters should be placed on the ETT connector and then the filter is connected to the breathing circuit and BVM unit. This allows for all expired air at the point of exit from the mouth to be filtered prior to entering the BVM which contains an open aerosolization port.

Breathing Circuit

The use of a single-line disposable breathing circuit aids in the maintenance of heated and humidified air returning to the patient and also allows for placement of the ApolloBVM at a safe distance from the patient.

Version 1 Phase 1 Testing

Respiratory Bag: Ambu Spur II I:E RATIO: 1:3

Percent Error:

| Respiratory Bag: Unknown I:E RATIO: 1:3

Percent Error:

|

Click HERE to see the Phase 1 testing results.

As updates are developed, they will be posted here.

Contact: apollobvm@rice.edu

ApolloBVM Design team

All design work on the ApolloBVM was done at the Oshman Engineering Design Kitchen at Rice UniversityDanny Blacker - Lead Designer

Dr. Maria Oden - Faculty Mentor

Dr. Matthew Wettergreen - Faculty Mentor

Thomas Herring - Controls Lead

Amy Kavalewitz - Project Manager

Dr. Rohith Malya - Clinical Lead

Fernando Cruz - Engineering Design Technician

Inspired by the 2018-2019 senior design project Team Take A Breather